What problems can we solve

In electronics and semiconductor industries, residues like organics and oxides often stay on products. Traditional cleaning may not remove them and can cause damage.

Pain point: Ordinary water washing or roller cleaning methods will incur the cost of cleaning consumables, and the cleaning effect on tiny pores and narrow gaps is not good.

Solution: Plasma cleaning technology is used to use the active particles in the plasma gas to physically collide or chemically react with pollutants, which not only does not use consumables, but also can efficiently remove various organic impurities.

Product Solutions

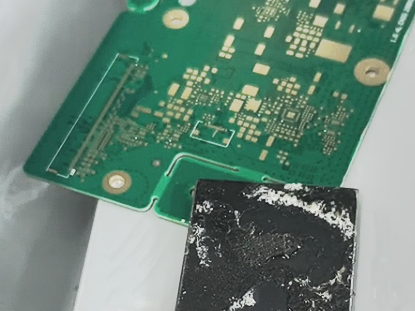

Circuit boards and molds in electronics factories often have flux, burrs, glue, oil, and other dirt that need efficient cleaning.

Pain point: Traditional cleaning methods may require disassembly of equipment, which increases cleaning time and cost dramatically. It is not only easy to damage the surface of the object being cleaned, but also increases the risk of equipment disassembly and installation.

Solution: Dry ice particles are used to remove dirt by supersonic impact, low-temperature thermal effect, and sublimation explosion effect. There is no need to disassemble, which is efficient and convenient.

Product Solutions

Dry ice needs to be properly stored during use to ensure its effectiveness and safety.

Pain point: Ordinary storage methods may cause dry ice to be consumed quickly and cannot meet the needs of long-term online use.

Solution: Recommend different storage solutions based on customer usage scenarios, such as ultra-low temperature storage freezers and medical insulation boxes for long-term online use.

Our solution is being applied in these industries