-

Video Introduction

-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Video Introduction

Intro to Residual Oxygen Shuttle in N2 Reflow

Intro to Residual Oxygen Shuttle in N2 Reflow

Product Value

Process stability assurance

Accurately detect the real data in the furnace to reduce the defective rate of product oxidation, cold soldering, etc.

Data-driven decision making

The oxygen concentration and temperature curves of multiple temperature zones are fully displayed, supporting process parameter tuning and improving equipment OEE

Equipment performance optimization

Quickly locate nitrogen leaks or temperature zone anomalies, reduce nitrogen waste, and save production costs

Compatibility and scalability

Adapt to all full tunnel nitrogen filling equipment to meet the stringent requirements of electronics, semiconductors and other industries

Core functions

Three-in-one full-area monitoring (oxygen concentration, temperature, orbital vibration, inclination)

Intelligent analysis and early warning

(automatically generate control charts and support customized alarms)

Customized expansion modules

(Evaluate air tightness and adapt to complex furnace bodies)

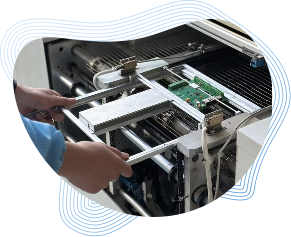

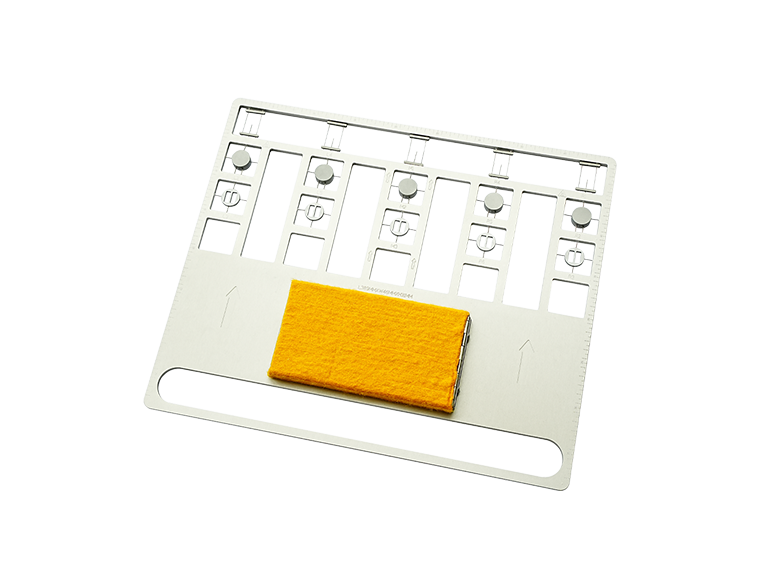

Highly compatible hardware design (ultra-thin body, adjustable carrier, high temperature resistance)

Applicable scenarios

Product parameters

| Oxygen concentration-sensor type | Replaceable concentration sensor |

| Oxygen concentration - measurement range | 0ppm-4000pm |

| Oxygen concentration - measurement accuracy | +1.5%FS |

| Oxygen concentration-whether preheating is required | Warm-up time required: 50 seconds |

| Track vibration - measurement direction | Three-axis output (XYZ) |

| Track vibration - measurement accuracy | +5% |

| Track vibration - measurement range | ±2G |

| Orbital vibration-resolution threshold | Resolution threshold (@1Hz) <1mg |

| Temperature measurement-number of channels | 2 channels |

| Temperature Measurement - Thermocouple Type | K-Type |

| Temperature measurement - measuring range | 0-750℃ |

| Temperature measurement - measurement accuracy | +0.5℃ |

| Instrument size L*W*H | 183mm*48mm*21mm |

| Insulation box size L*W*H | 242mm*90mm*34mm |

| Carrier size L*W*H | ①Minimum adjustment width (248mm*145mm*35mm) > ②Maximum adjustment width (248mm*284mm*35mm) |

Related materials

ROS Residual Oxygen Shuttle

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you