-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Product Value

Flexible Adaptation

The small size design can easily cope with narrow furnace openings and is compatible with a variety of reflow oven scenarios.

Accurate and efficient

High-precision temperature measurement (±0.5°C) reduces process deviation and improves product yield.

Smart Analysis

Automatically generate process window reports to quickly locate process anomalies and reduce quality risks.

Convenient management

Data can be exported with one click (TXT / Excel / PDF) to facilitate traceability and compliance auditing.

Core functions

Real-time monitoring: Display temperature curve.

Process analysis: set the process window and determine the pass rate.

PIS index: Evaluate process stability and generate reports.

Abnormal warning: over-temperature alarm, prompt communication status.

Smart storage: save 30 sets of data.

Applicable scenarios

Product parameters

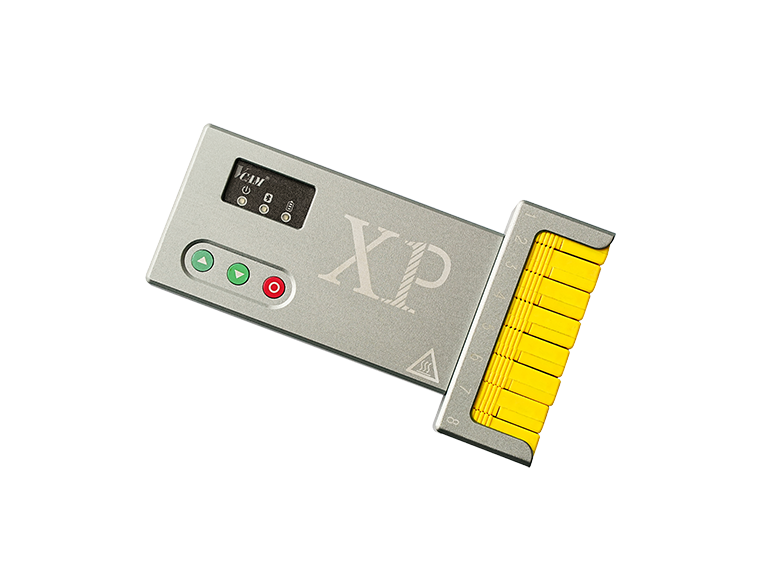

| Model | XP107S, XP109S, XP113S |

| Number of channels | 7 channels, 9 channels, 13 channels |

| Profiler size (mm) | L146×W61×H19 mm, L146×W78×H19 mm, L146×W110×H19 mm |

| Corresponding insulation box size | L345×W114×H35 mm, L345×W130×H35 mm, L345×W162×H35 mm |

| Probe Type | K-Type |

| Acquisition rate | 0.1~ 30s |

| Data Transfer | USB connection for data transfer |

| Continuous testing | Can test multiple times, store up to 30 data |

| Startup method | Button start, delay start, temperature start |

| Instrument temperature resistance | 0-85℃ |

| Operating voltage | DC5V1A |

| Instrument accuracy | ±0.5 ℃ |

| Resolution | 0.1 ℃ |

| Measuring range | 0 to 750°C |

| Stop method | Button stop, temperature stop |

| Memory capacity | 86400 Point |

| Insulation box material | Stainless steel insulation sleeve |

| Operating system | Microsoft Windows 7 (32-bit or 64-bit) or above/Dual-core 1GHz processor PC/4G memory/40G hard disk storage/1280*1024 video resolution 16-bit/1 available USB port (for data download) |

Related materials

XP High Performance Oven Profiler

Recommended products

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you