What problems can we solve

Reflow oven performance test scenario

Scenario: During reflow, furnace temperature, oxygen levels, and track performance greatly affect welding quality, so real-time monitoring is needed.

Pain Point: Without accurate insight into process conditions, it’s hard to spot problems, which harms quality and efficiency.

Solution: Use various equipment to monitor reflow oven performance, including thermal balance, uniformity, and efficiency.

Product Solutions

Reflow temperature real-time monitoring scene

Scenario: During reflow soldering, real-time reflow temperature monitoring is needed to ensure each PCB follows the correct temperature curve.

Pain Point: Traditional methods struggle to monitor temperature curves for each PCB individually and fail to meet quality traceability needs.

Solution: Use the vacuum reflow real-time monitoring system (PIS) to create exclusive, traceable temperature and vacuum curves for every PCB.

Product Solutions

Multi-parameter real-time monitoring scenario

Scenario: During reflow soldering, factors like rail vibration, hot air motor speed, and oxygen levels affect soldering quality. Multiple parameters must be monitored at once.

Pain Point: Single devices can’t monitor multiple parameters simultaneously, leading to incomplete data and delayed detection of issues.

Solution: Use multi-channel oxygen analyzers, real-time rail vibration monitors (VIS-V), and hot air motor speed monitors (VIS-F) for simultaneous real-time monitoring.

Product Solutions

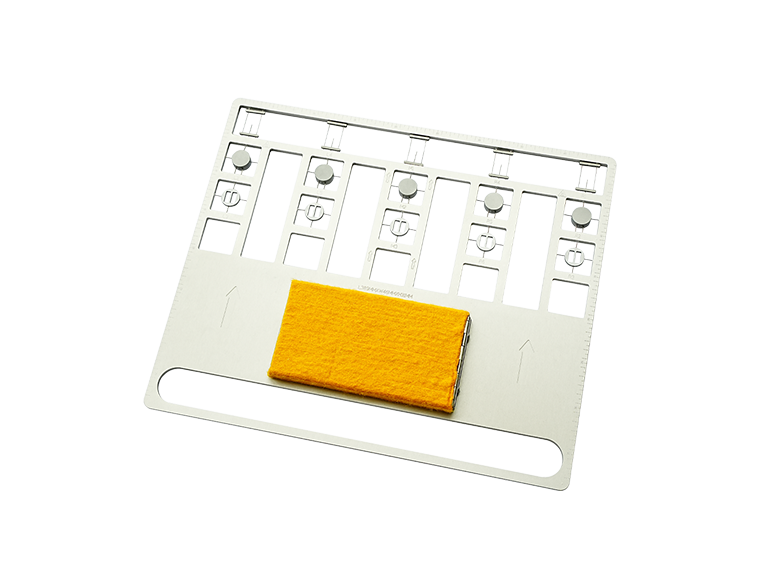

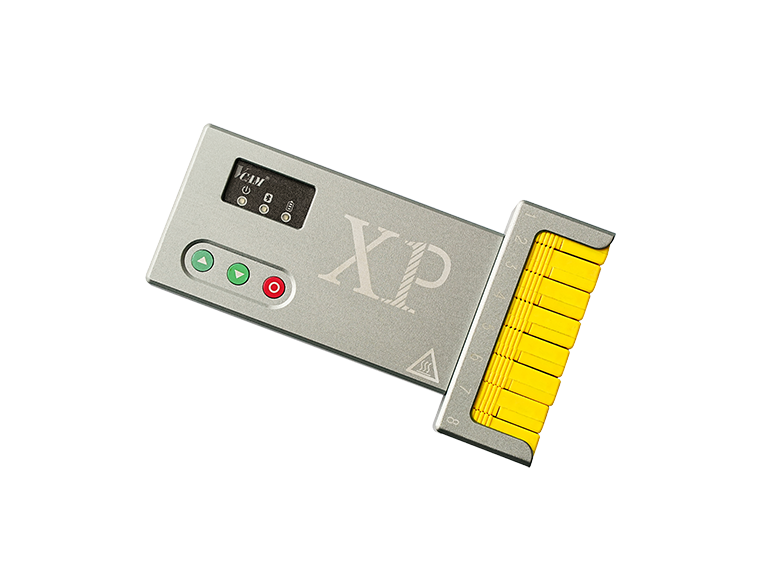

Temperature Check Scene

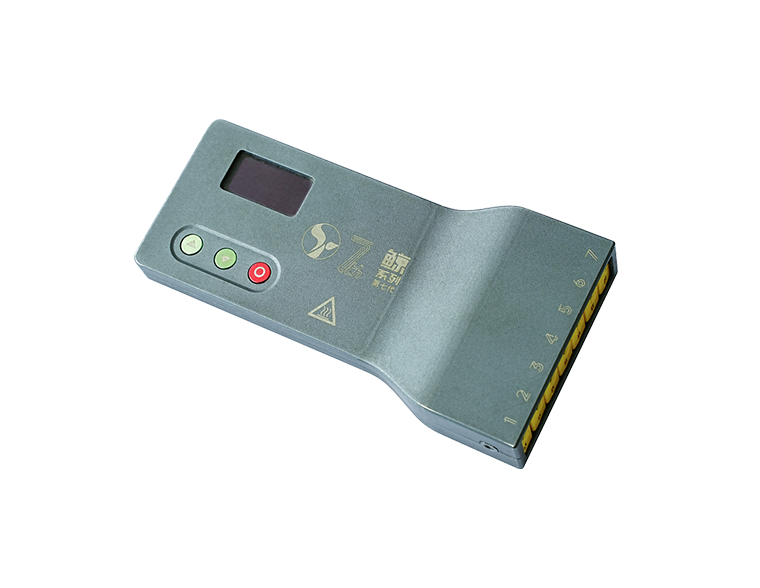

Scenario: Accurate furnace temperature detection during reflow soldering is essential for quality. This requires precise and easy-to-use temperature detection equipment.

Pain Point: Traditional equipment may lack accuracy, struggle with different reflow ovens, and have delayed data transmission.

Solution: Offer customizable furnace temperature testers with high-precision data capture, wireless transmission, and breakpoint resume features.

Product Solutions

Our solution is being applied in these industries