-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Product Value

Nitrogen consumption control

Enhanced supply stability

Intelligent Energy Consumption Diagnosis

Multi-purity scenario coverage

Core functions

Intelligent nitrogen consumption reduction for idle production lines

Nitrogen is instantly connected when production starts

Self-regulation of nitrogen flow during production

Nitrogen cost-effectiveness saving function

Multi-sensor real-time gas usage monitoring

Flow and pressure automatic matching technology

Applicable scenarios

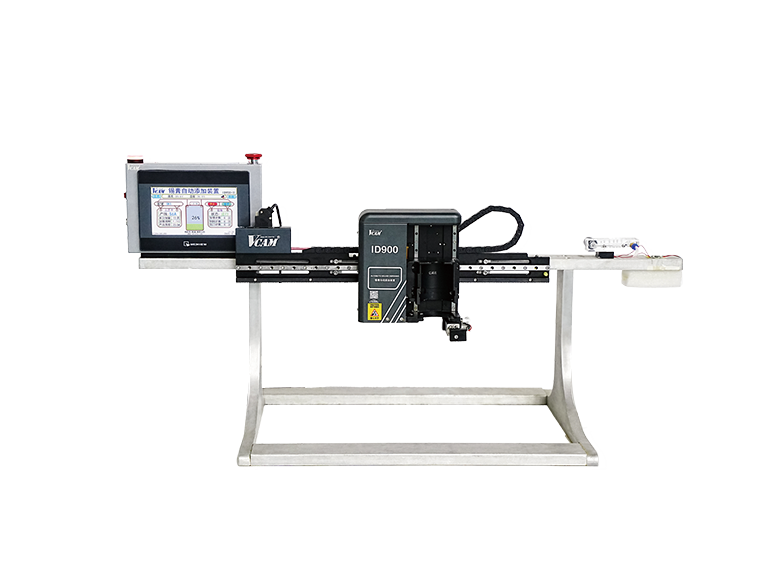

Product parameters

| Nitrogen flow rate | 0-30m3/h |

| Nitrogen pressure | 0-0.8Mpa |

| Control flow rate | 0-30m3/h |

| Data port Interface | RS485/4-20mA/Ethernet |

Related materials

Nitro saver

Recommended products

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you