-

Video Introduction

-

Product Value

-

Core functions

-

Applicable scenarios

-

Parameter comparison

-

Related materials

-

Recommended products

Video Introduction

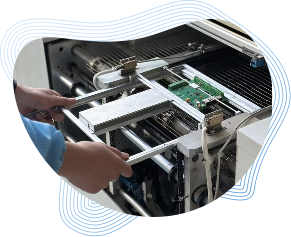

How parts are soldered to a PCB in a reflow oven

How parts are soldered to a PCB in a reflow oven

Product Value

Process Optimization

Use high-definition video to trace the welding process, accurately identify process defects, and optimize parameters

Improved efficiency

Quickly locate abnormal problems, reduce downtime and troubleshooting time, and improve production efficiency

Fault prevention

Real-time monitoring of temperature and vibration data, early warning of potential risks, and reduced rework rates

Quality traceability

Completely record welding process data and provide visual basis for quality audit

Core functions

High-definition video recording: Capture welding details and support more than 20 times optical magnification observation.

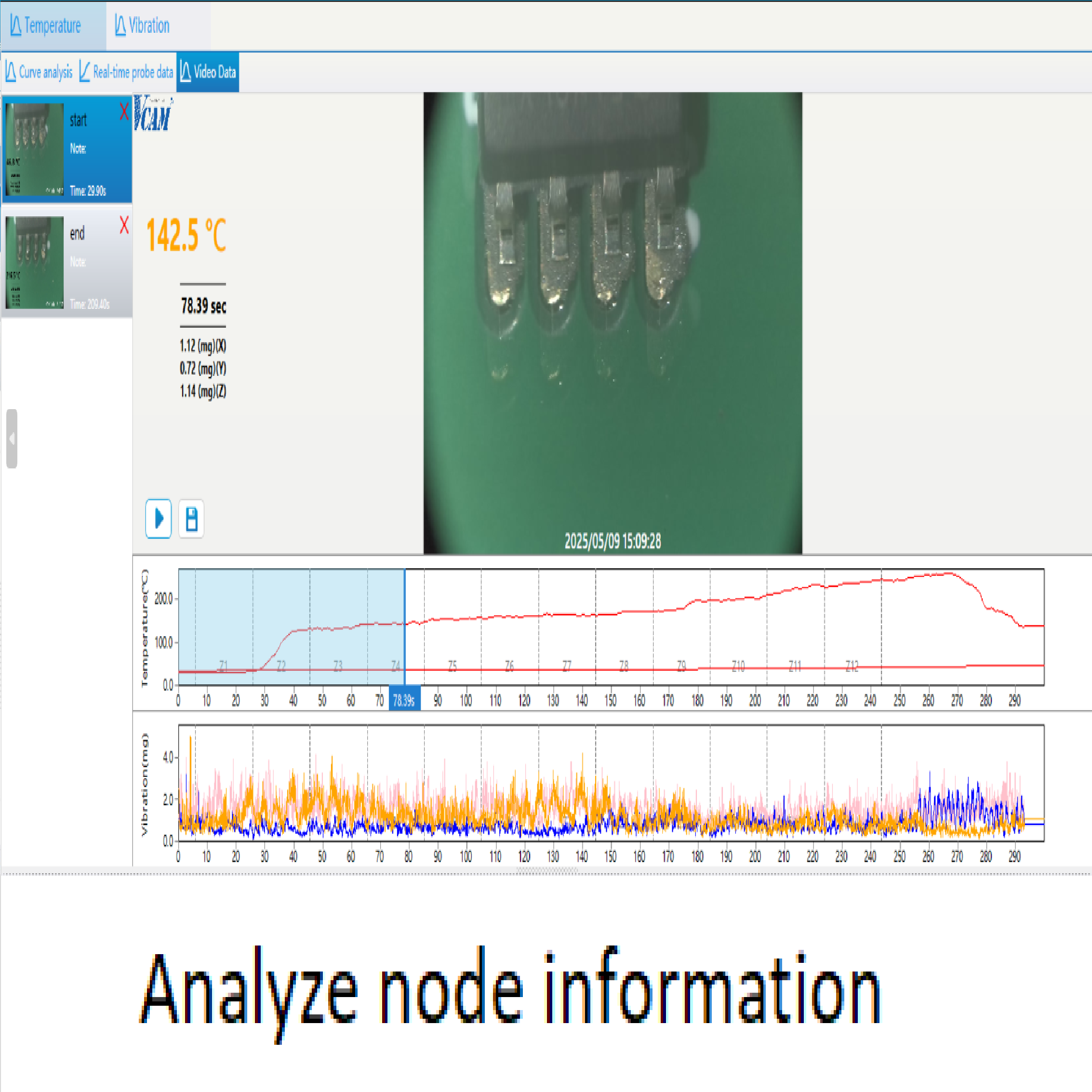

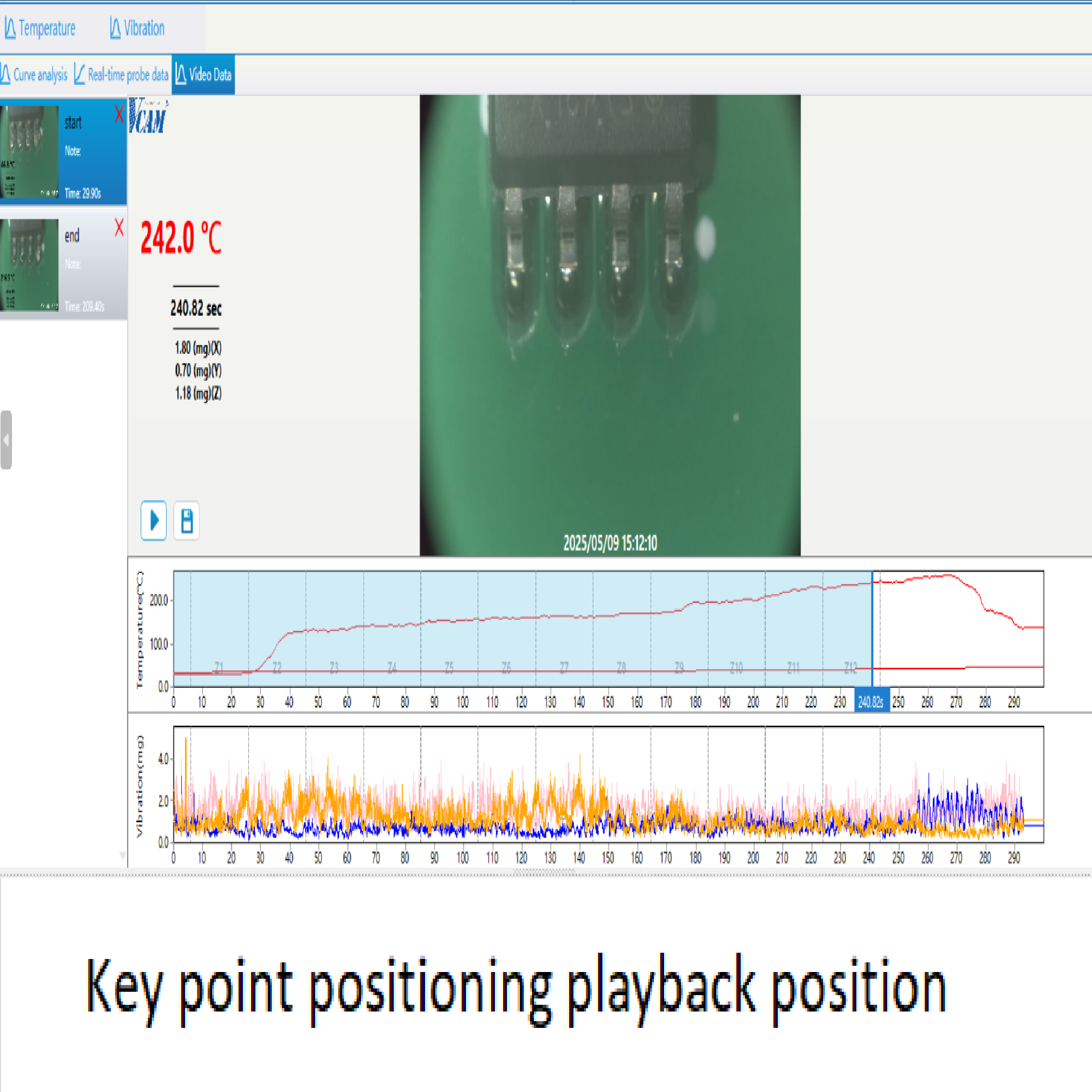

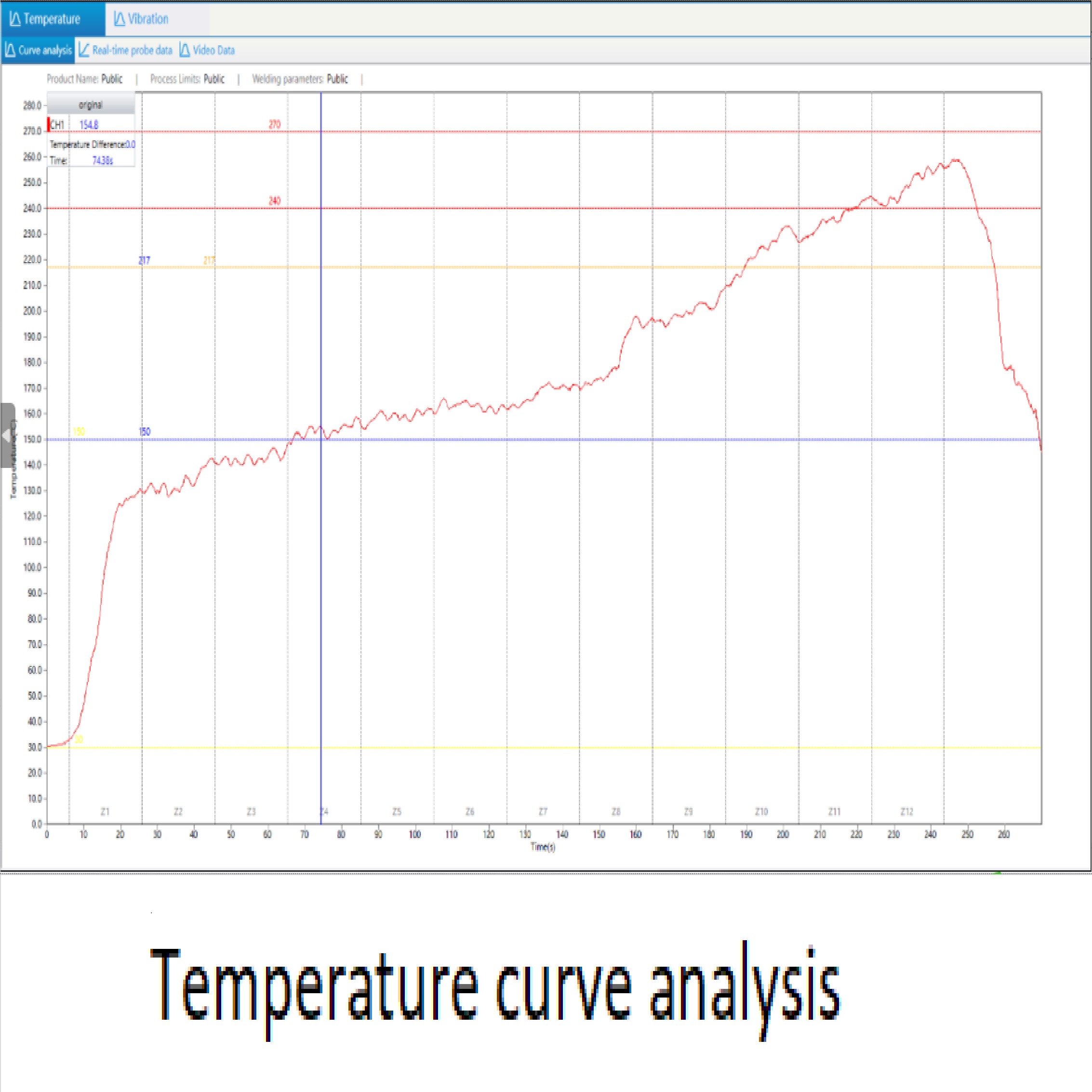

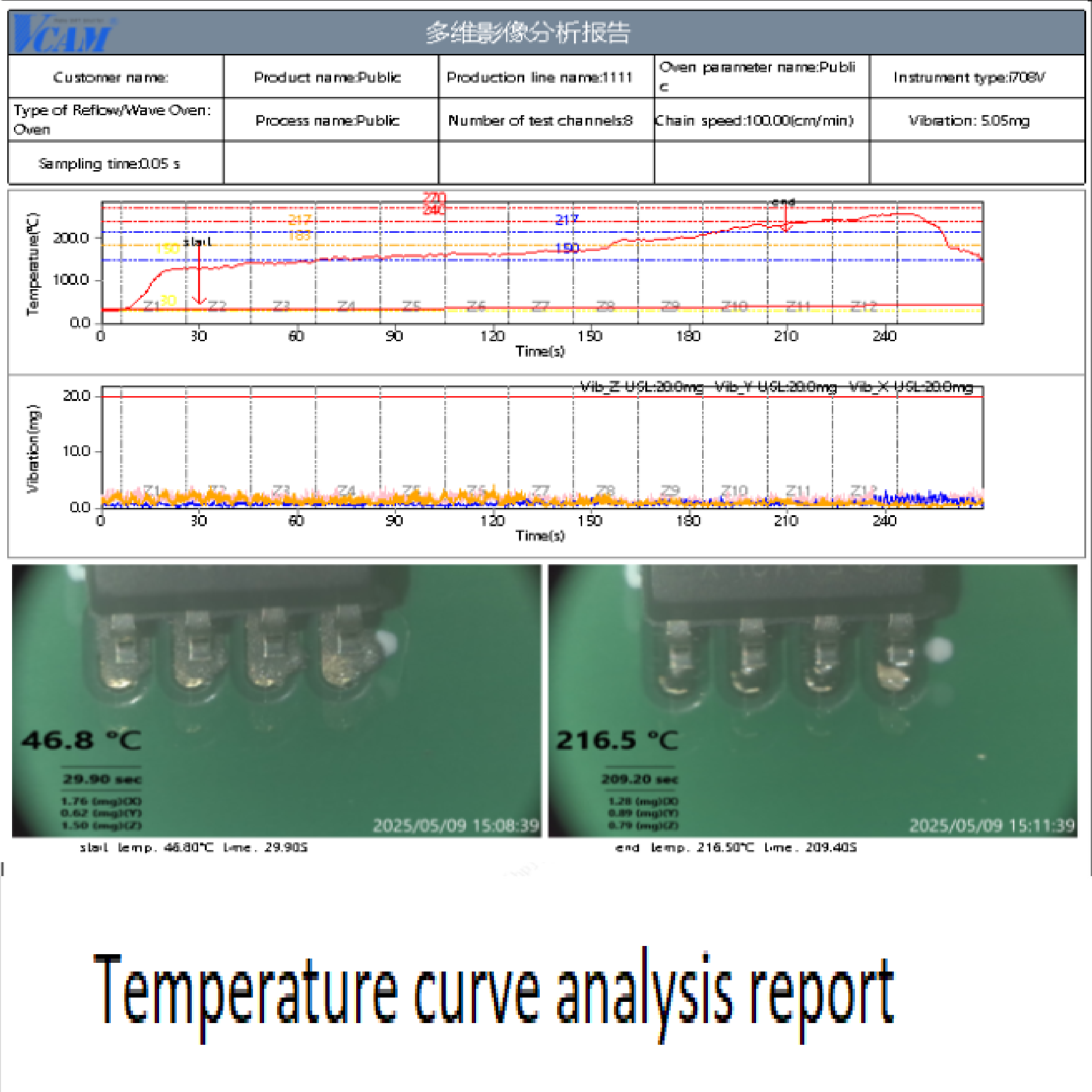

Accurate temperature measurement: lock the image and temperature point at the moment of abnormal welding defects.

Track Vibration Analysis: Simultaneous analysis of track vibrations.

Intelligent report generation: integrates video, temperature, and vibration data for rapid location and analysis.

Support mobile terminals: conveniently view the details of the welding process in real time.

PC download analysis: Supports Windows to download high-definition video analysis reports of the welding process.

Applicable scenarios

Parameter comparison

Related materials

Reflow Soldering Vision Pro

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you