-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Product Value

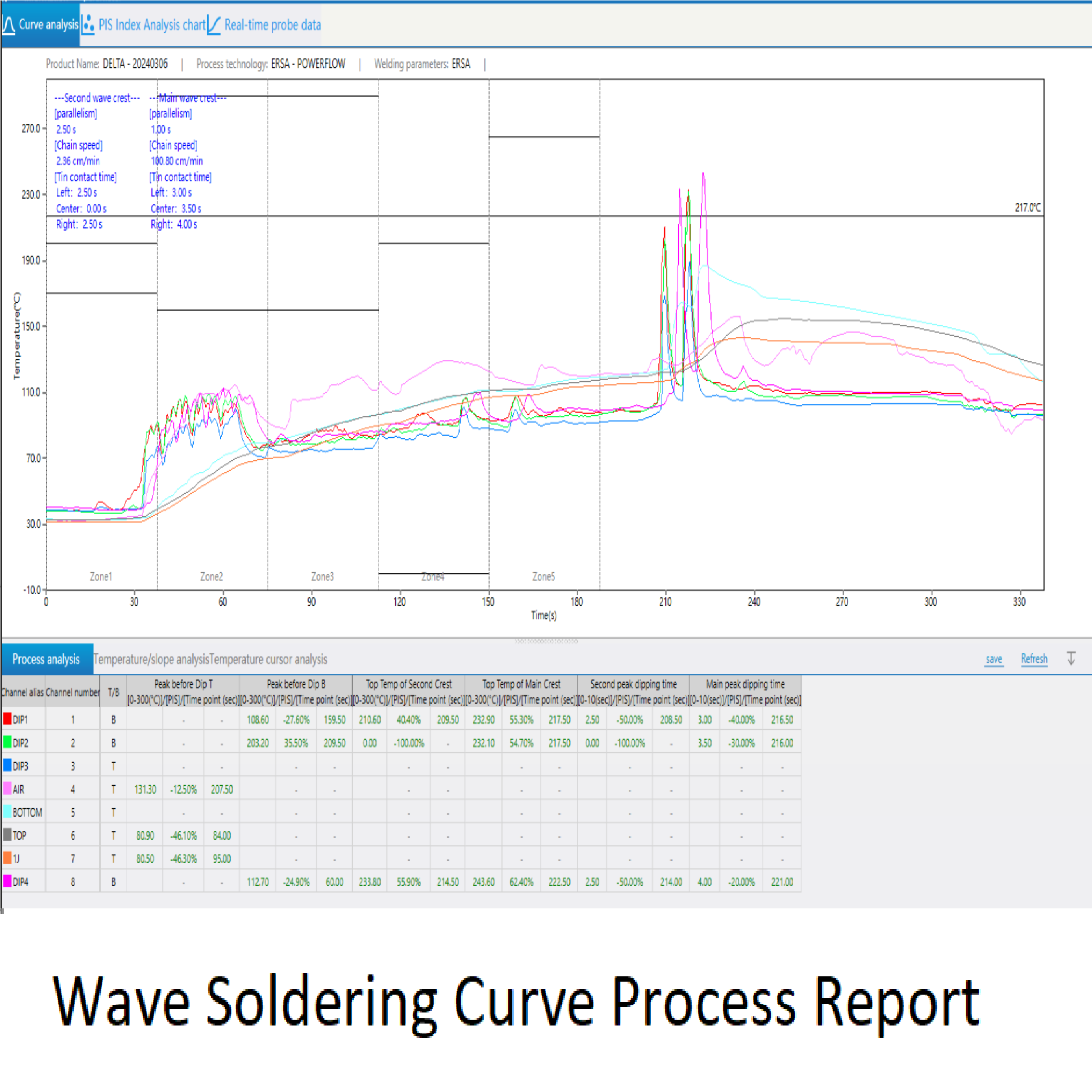

Process Optimization

Accurately analyze the soldering time and temperature to reduce the problems of false soldering and leaking soldering

Cost Control

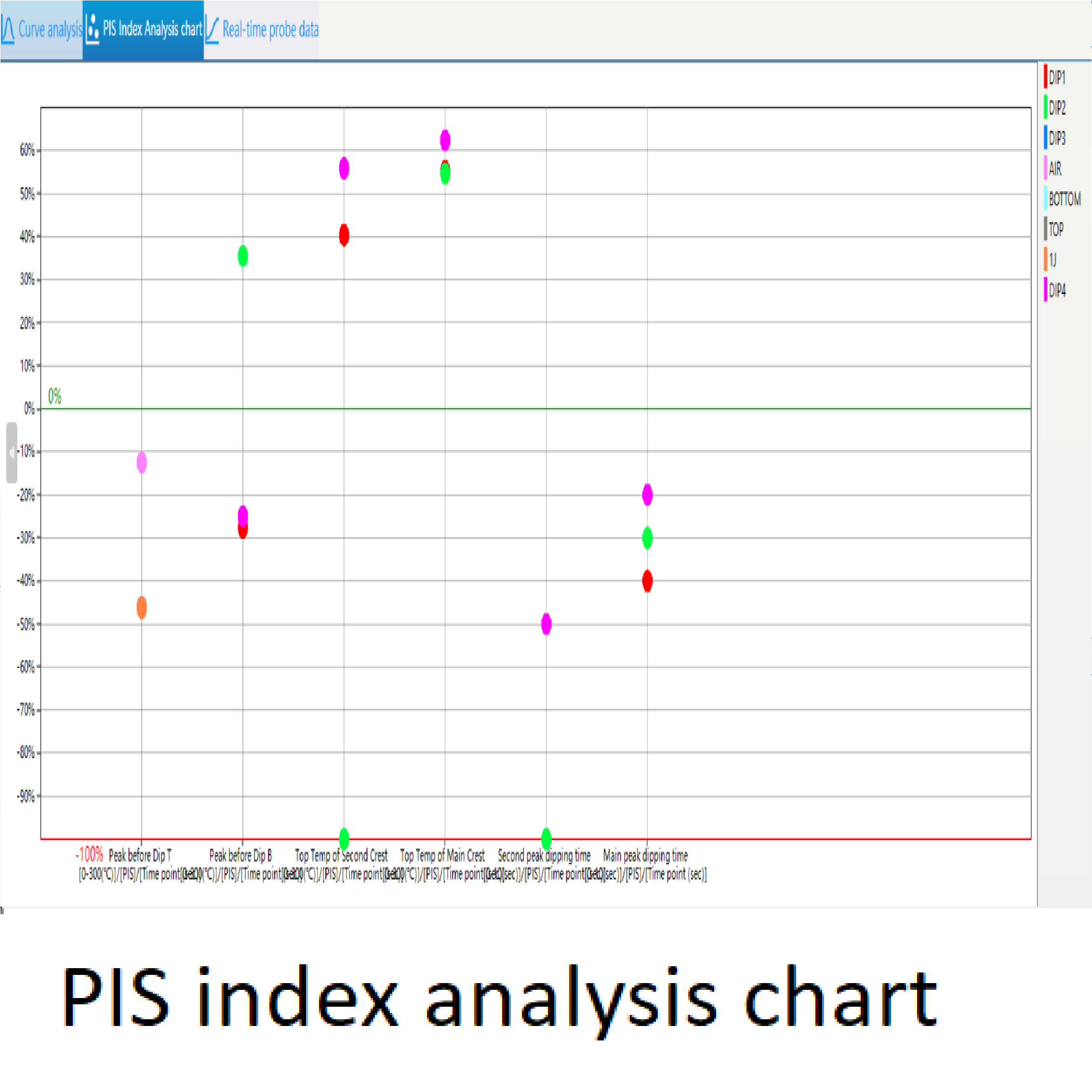

Reduce rework rate and energy consumption through process window index (PIS) analysis

Fault prevention

Real-time monitoring of chain speed fluctuations and track parallelism, early warning of equipment abnormalities

Data-driven decision making

SPC statistics and CPK calculation provide quantitative basis for process improvement

Core functions

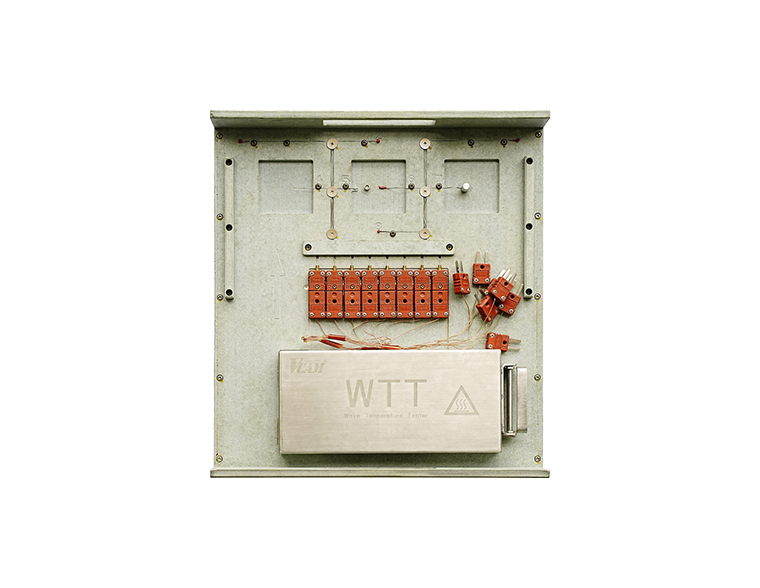

Temperature detection

Real-time monitoring of temperature changes in each channel

DIP analysis

Accurately measure the tin contact time and temperature

Track inspection

Analyze chain speed and parallelism to ensure track stability

Intelligent Optimization

Predict temperature trends and optimize process parameters

Data Analysis

Automatically generate SPC charts and CPK values and provide visual reports

Extended support

Compatible with mainstream wave soldering equipment, supporting multi-channel synchronous acquisition

Applicable scenarios

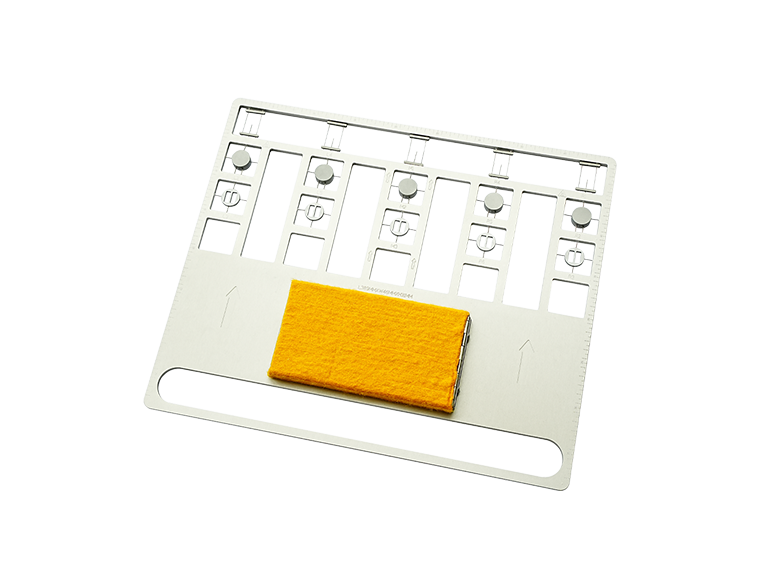

Product parameters

| Accuracy | ±0.5℃ |

| Resolution | 0.1℃ |

| Instrument Channel | 8 |

| Sampling frequency | 0.1S ~ 20S |

| Power supply | 5V1A |

| Communication | USB |

| Thermocouple Type | K-Type |

| Appearance | 300x330x52mm |

Related materials

WAPS wave soldering temperature real-time monitoring system

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you