-

Product Value

-

Core functions

-

Applicable scenarios

-

Parameter comparison

-

Related materials

-

Recommended products

Product Value

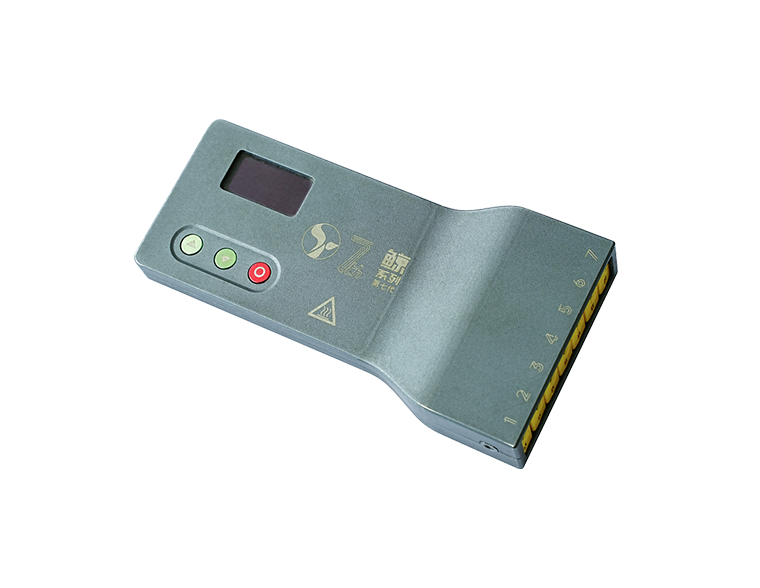

Dual-mode visualization

Support screen display of temperature and power, easy to use

Efficient cost reduction

Reduce reliance on manual testing, obtain data immediately after testing, and shorten the debugging cycle.

Flexible Adaptation

Supports 7/9/13 channel customization to meet the needs of diverse production lines.

Convenient management

Large storage capacity + one-click report printing to achieve data traceability.

Intelligent Decision Making

SPC analysis and curve simulation functions can help you avoid process risks in advance.

Core functions

Real-time curve monitoring: LCD screen displays temperature and power, and data is visualized.

AI temperature prediction: intelligently predict trends and detect anomalies in advance.

Resume transmission: wireless transmission is anti-interference and automatically restores the connection.

Standard process analysis: automatically match standards and generate compliance rate reports.

SPC statistical analysis: compare data from multiple batches to optimize process stability.

Long battery life: 4 hours of ultra-long battery life.

Multi-channel customization: support 7/9/13 channel configuration.

Applicable scenarios

Parameter comparison

Related materials

i7 S-type Series Intelligent Oven profiler

Recommended products

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you