-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

Product Value

Cost savings

No need to change solder paste packaging, reducing material waste and procurement costs

Improve efficiency

Remote monitoring - One person multiple machines mode Reduce labor costs Improve production efficiency

Stable quality

Real-time monitoring of temperature and humidity, precise quantitative addition of solder paste, and guaranteed printing quality

Intelligent management

Automatically calculate the number of times the stencil and squeegee are used to optimize production planning

Core functions

Automatic quantitative addition: servo motor accurately adds solder paste

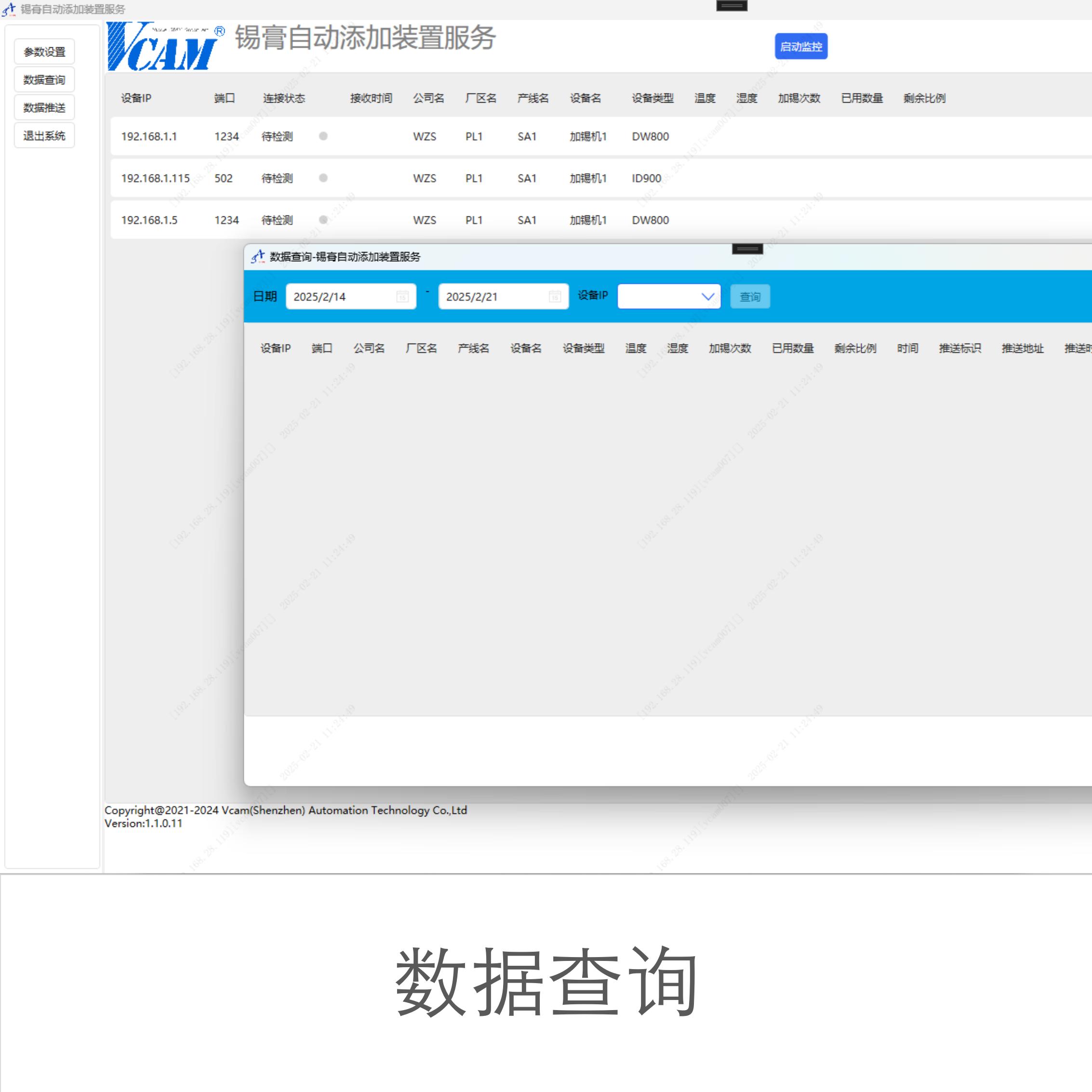

Remote monitoring: remote control, real-time monitoring of temperature and humidity

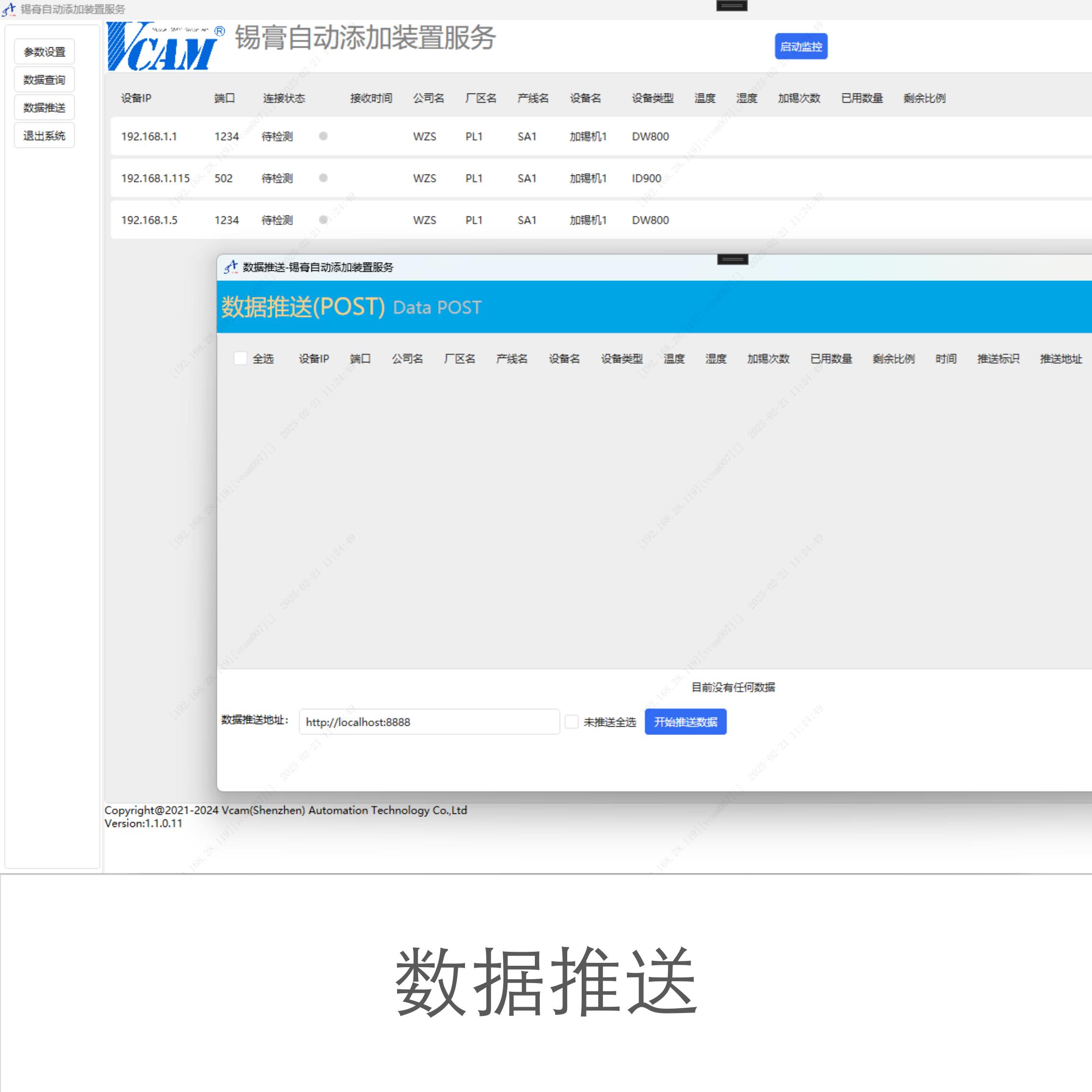

Data storage and tracking: record usage and optimize maintenance

Permission settings: multi-user management to ensure security

Mobile addition: adapt to different production lines

Smart reminder: abnormal temperature and humidity reminder

Applicable scenarios

Product parameters

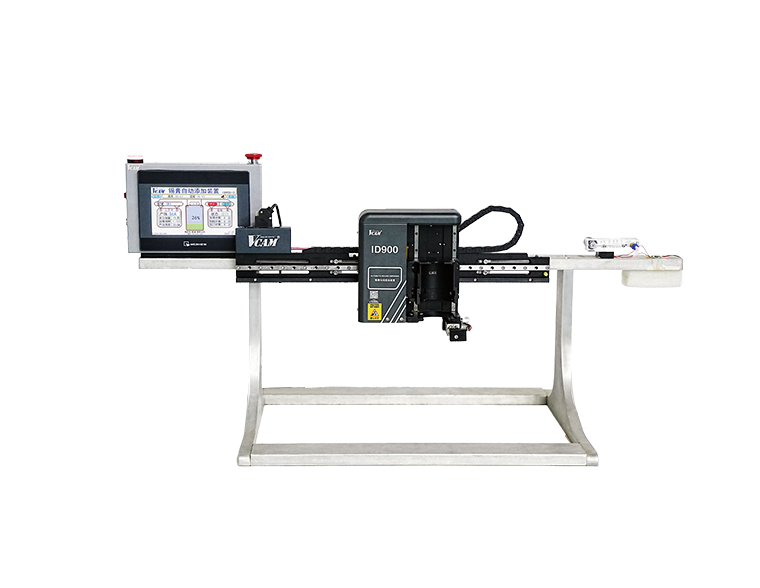

| Model | ID900 |

| Size | 182(w)×101(D)×232(H)mm |

| Tin feeding accuracy | ±0.5g |

| The compatible capacity of the solder paste | 500g, Customizable 250g |

| Tin output control amount | 5-99g |

| Tin addition setting range | 5-30g |

| Tin addition method | Fixed position addition, X direction movement addition |

| Suitable for printing press | Various domestic and imported solder paste printing machines |

| Warning method | Buzzer and tri color light |

| Power supply | AC100-260V 50-60HZ |

| Weight | 4.3kg |

Related materials

Automatic solder paste dispenser

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you