-

Video Introduction

-

Product Value

-

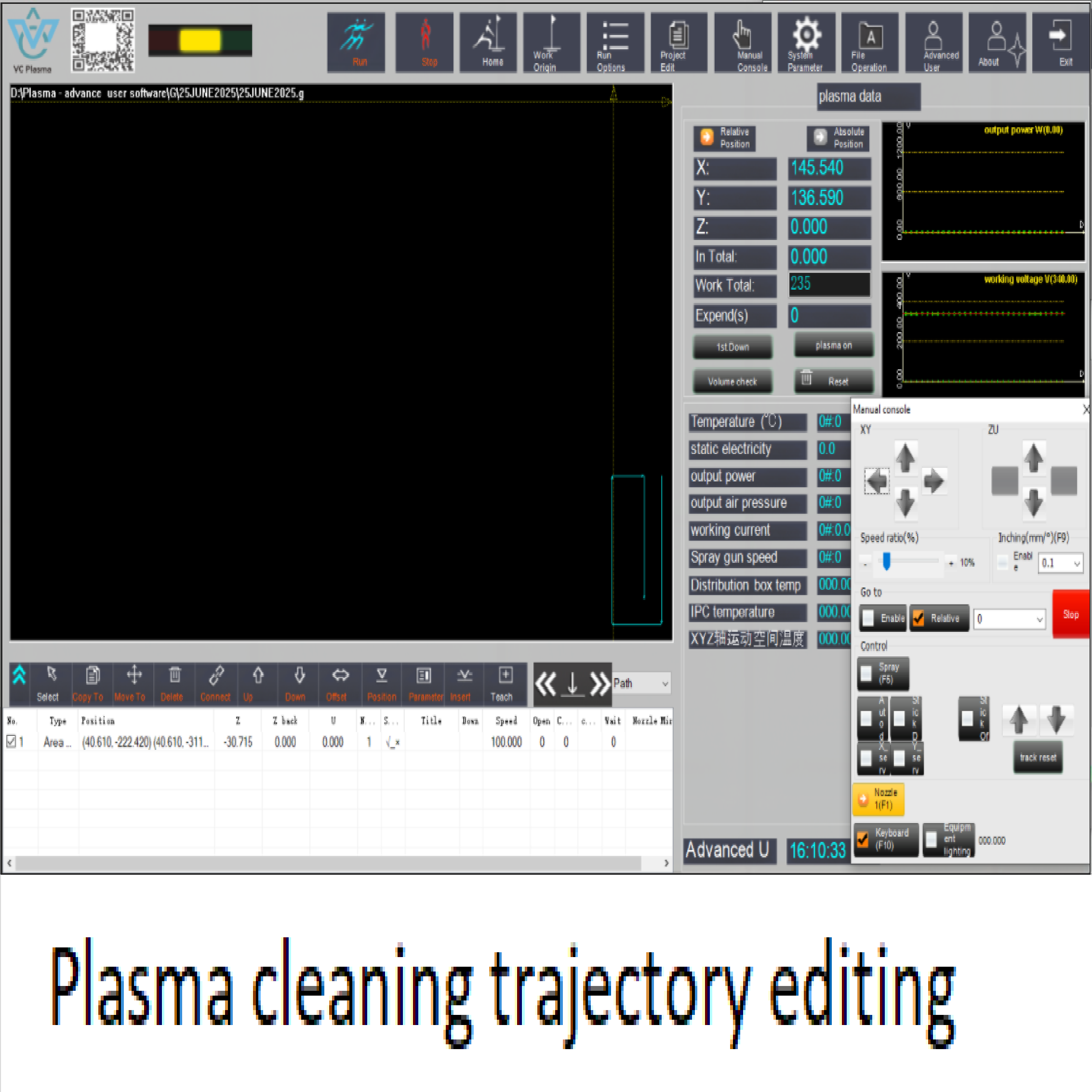

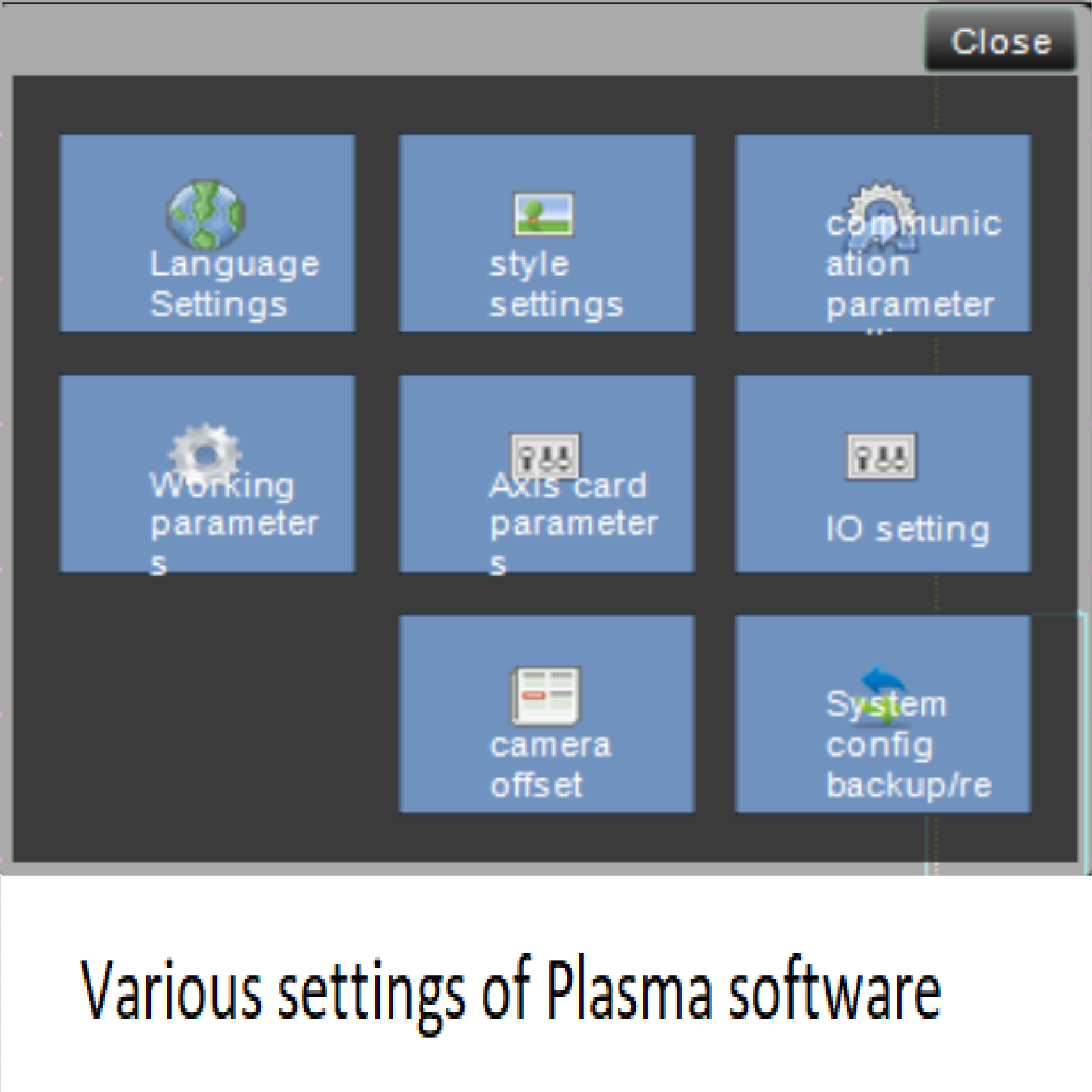

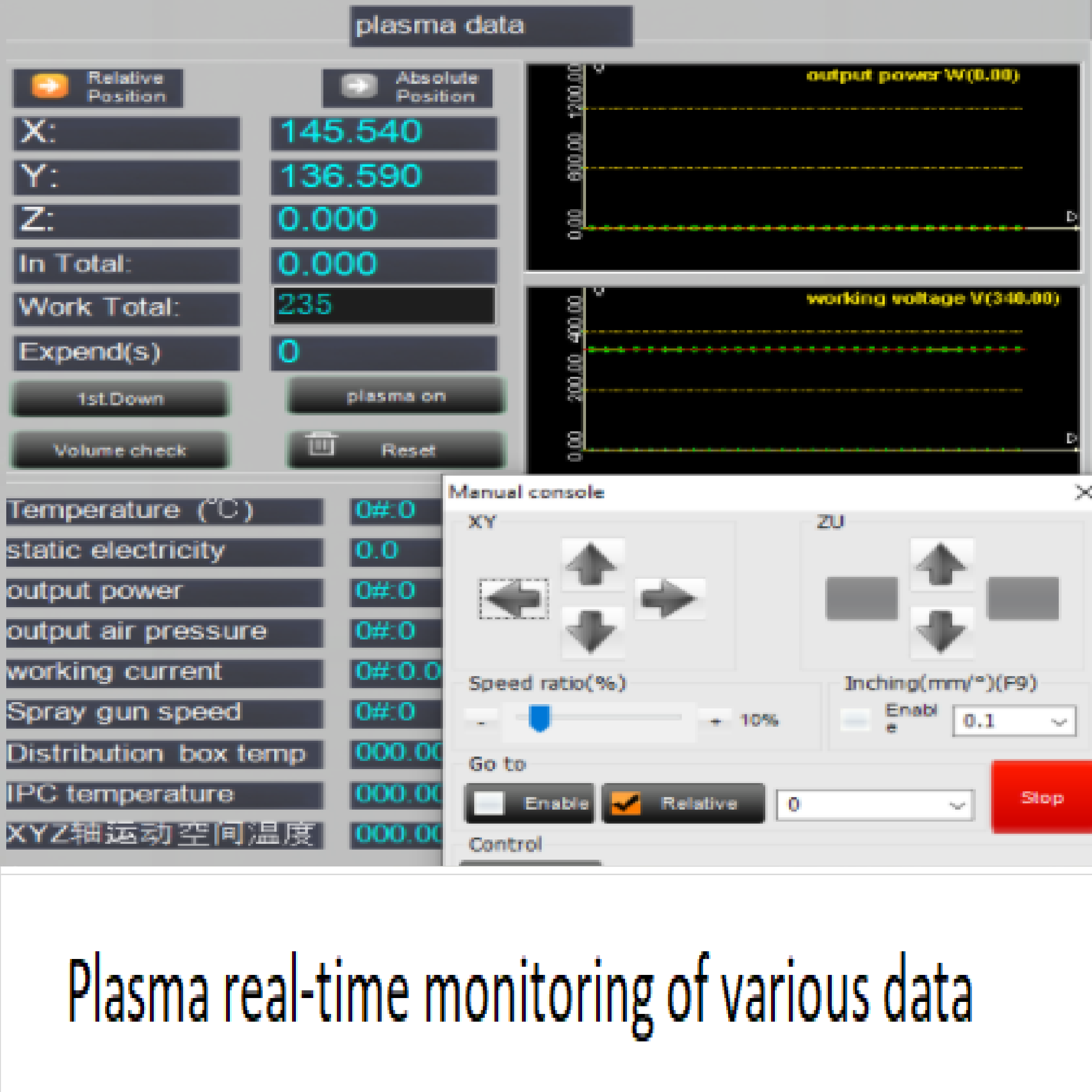

Core functions

-

Applicable scenarios

-

Product parameters

-

Recommended products

Video Introduction

Inline plasma cleaning equipment

Inline plasma cleaning equipment

Product Value

No chemical solvents required, reducing usage costs

Support automation integration to improve production line efficiency

Adapt to the high-precision cleaning needs of multiple industries

Core functions

Cleaning: Remove pollutants, oxide films and dust to lay the foundation for subsequent processing.

Activation: Generate polar groups, enhance chemical properties, and improve wetting and bonding properties.

Improve surface energy: enhance bonding strength, make the process more solid, and improve stability and life.

Environmentally friendly formula: non-toxic and harmless, safe discharge, protects health, and leads green production.

Applicable scenarios

Product parameters

| Axis Number | 6-axis controllable X, Y, Z, track |

| Control method | PC industrial control + servo closed-loop motor |

| Maximum movement speed | 500mm/s |

| Positioning accuracy | ±0.1mm |

| Repeatability accuracy | ±0.05mm |

| Maximum component height | Conveying surface: 80mm on top, 30mm on bottom. Please refer to the actual product. |

| AM speed | 250mm/min |

| Conveyor height | 900±20mm |

| Conveyor speed | 2-5m/min |

| Transmission Type | Anti-static belt (optional) |

| Transmission direction | L → R (R → L optional) |

| Marginal Space | ≥ 3mm |

| Maximum load | 4kg/m evenly distributed |

| Equipment area | L650×W1300×H1500mm |

| Power supply | AC220V 10A 50/60HZ |

| CDA | 0.6Mpa air source |

| Plasma power supply | Digital power supply (optional) |

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you