-

Video Introduction

-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

FAQ

Video Introduction

PIS24-365

PIS24-365

Product Value

Millisecond-level intelligent control, zero process deviation

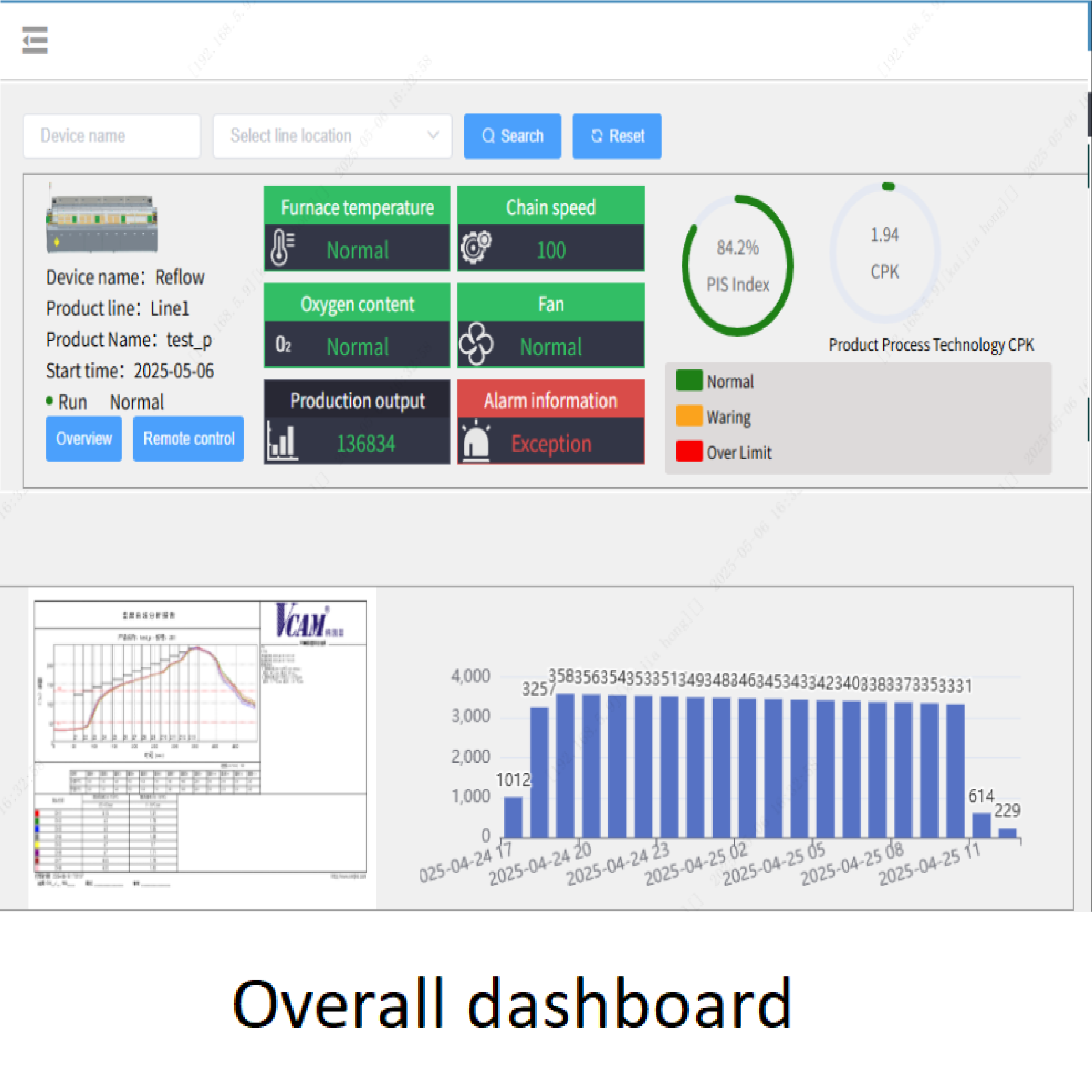

Achieve full-process traceability and accurately locate quality issues and anomalies.

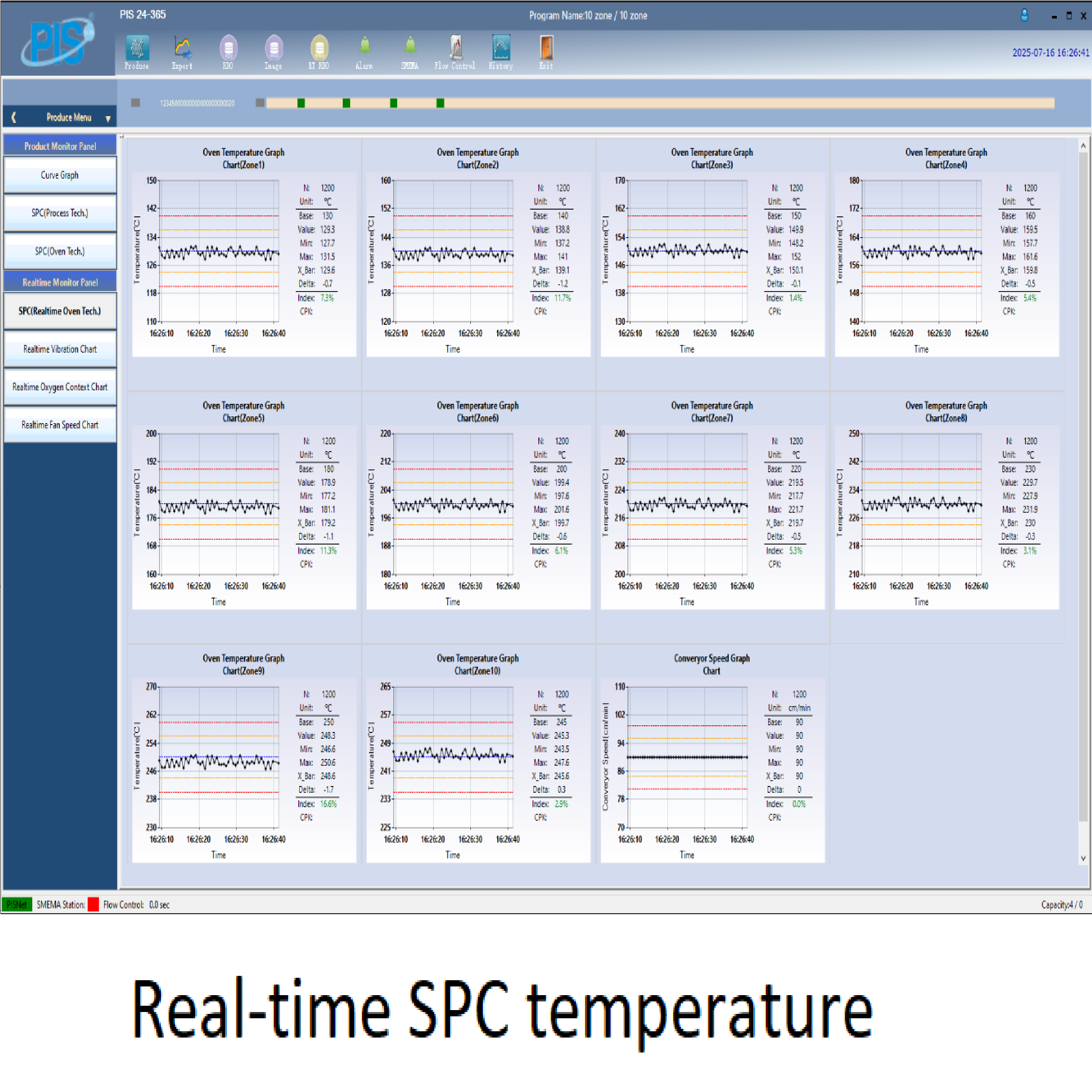

Core functions

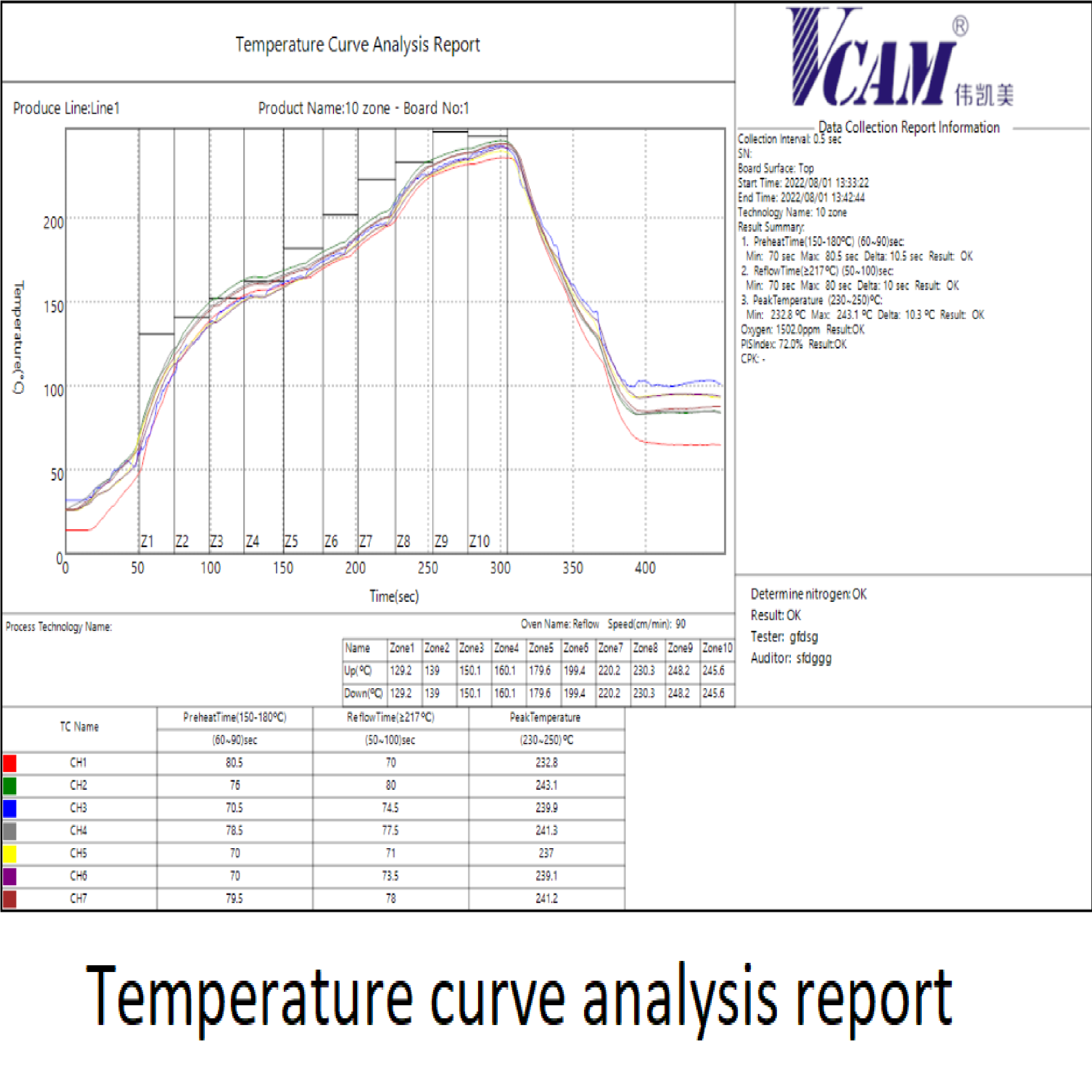

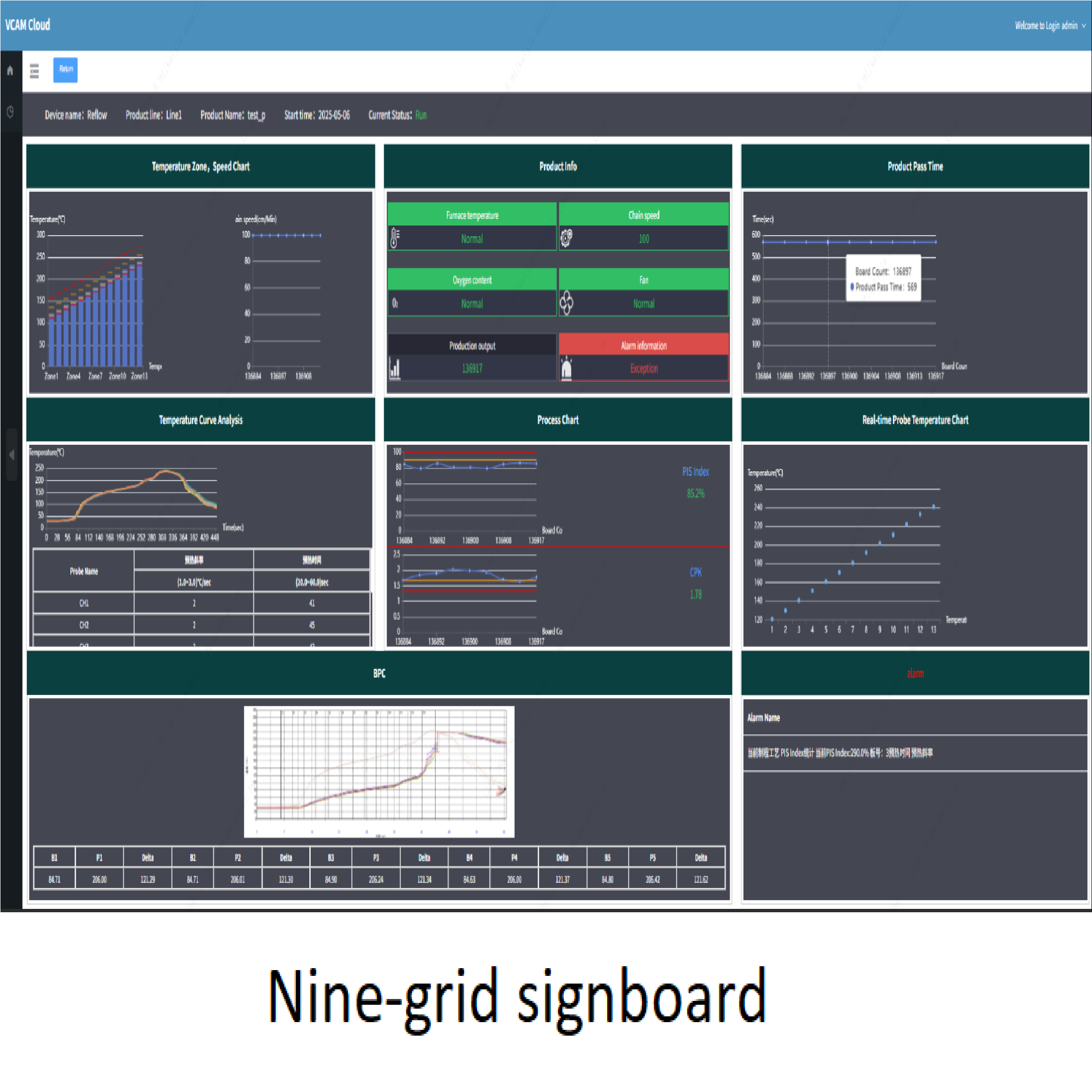

Multi-source data fusion: 40-channel temperature curve (±0.5℃ accuracy) + vacuum pressure (0-100kPa range) synchronous acquisition

Multi-physics simulation: 3D thermal field dynamic simulation and vibration frequency domain spectrum overlay analysis

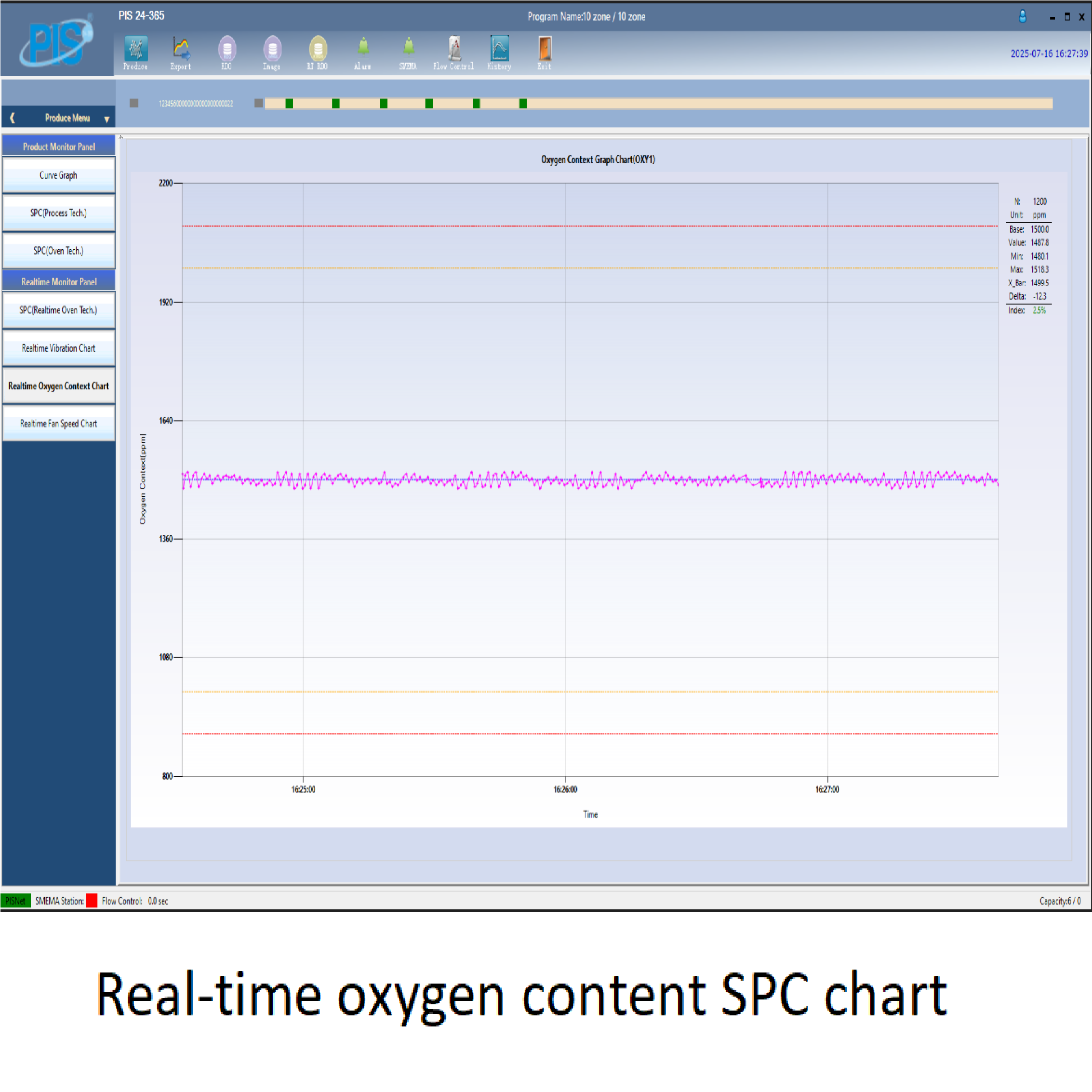

Intelligent compliance engine: CPK/PWI/Six Sigma multi-dimensional process capability matrix automatic evaluation

Extended architecture: optional track chain speed/gas flow/motor speed monitoring module

Applicable scenarios

Product parameters

| Accuracy | +0.5℃ |

| Resolution | 0.1℃ |

| Temperature measurement points | 20-38 |

| Maximum number of channels supported | 40 |

| Chain speed measurement accuracy | ±1% |

| Temperature measurement range | 0-750℃ |

| Temperature measurement resolution | 0.1℃ |

| Communication | Ethernet |

| Power Requirements | 24V 1.5A |

| Barcode scanner access | Support 2 RS232 port input |

| Device weight | 1.5KG |

| Device size | L150*W190*H50 mm |

| Compatibility | Compatible with most brands of profiler |

Related materials

PIS real-time temperature monitoring intelligent system

FAQ

Which is better for cleaning: dry ice or plasma?

Dry ice cleaning is mainly a physical method to clean stubborn stains, burrs, rosin, furnace surfaces, etc.

Plasma is mainly a chemical method, and physics plays an auxiliary role, activating the surface of the object, increasing the surface energy, and enhancing the surface adhesion.

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you