-

Video Introduction

-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Video Introduction

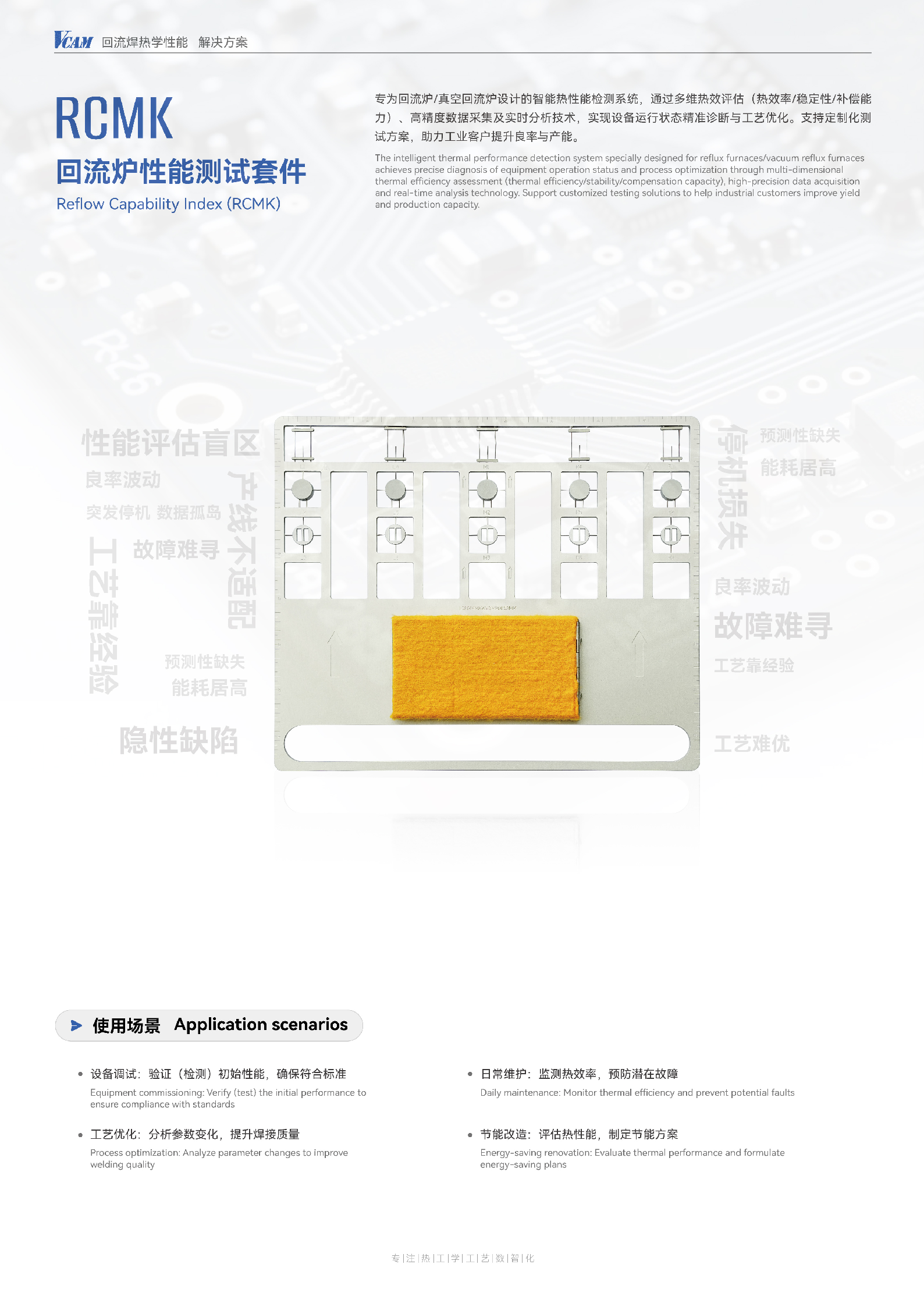

Rcmk reflow performance test kit

Rcmk reflow performance test kit

Product Value

Accurate diagnosis

Multi-channel data acquisition (±0.5℃ accuracy) and real-time analysis to quickly locate equipment problems

Flexible production

Support customized test suites to meet diverse scenario requirements and adapt to production lines of different scales

Efficiency Optimization

Improve production capacity and reduce energy consumption through thermal efficiency analysis

Systematization of operation and maintenance guarantee

Build a full-cycle equipment health management system to reduce the risk of unplanned downtime

Core functions

Thermal performance analysis

(assessment of balance, uniformity and stability)

Dynamic detection

(testing thermal shock, thermal convection change and other indicators)

Intelligent analysis

(generate quality control charts, support multi-channel data acquisition)

Visual report

(intuitively displays results and provides suggestions for improvement)

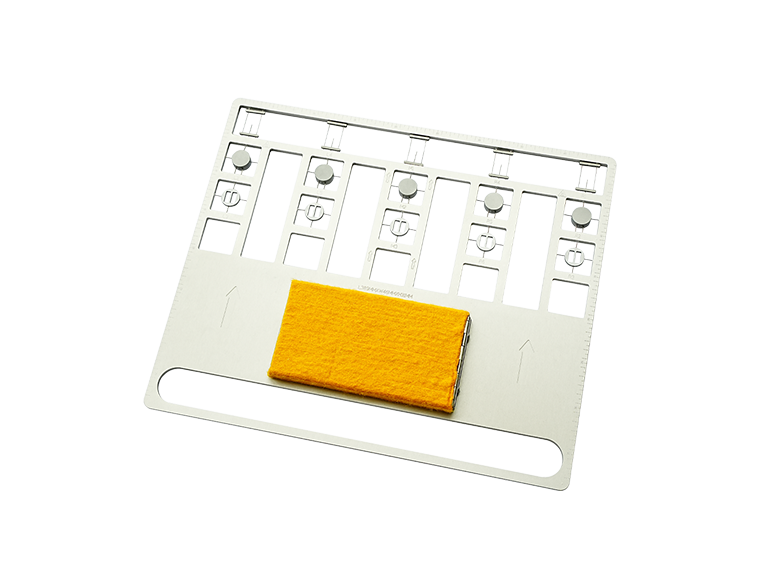

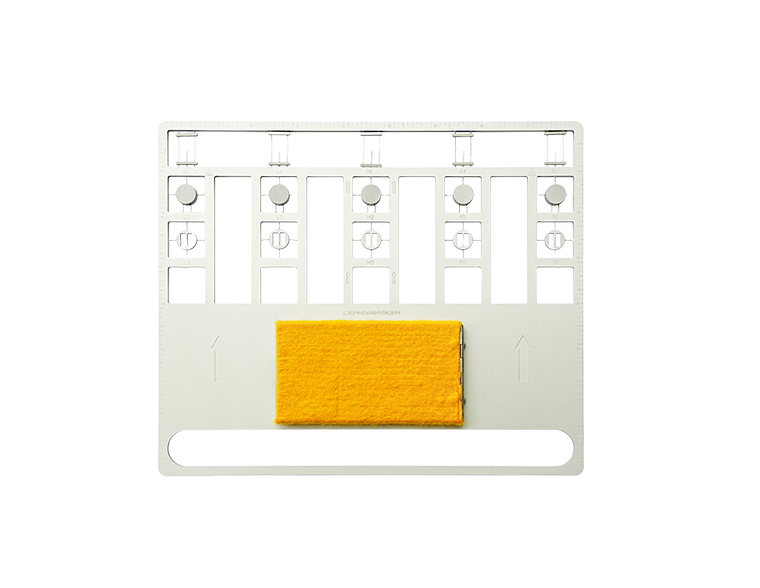

Hardware support

(provides a variety of specifications to meet different needs)

Expansion capability

(support customized test suites, flexible adaptation to production lines)

Applicable scenarios

Product parameters

| Data Logger | iProfile Super |

| Number of supported channels | 12 channels (9 temperature measurement channels + 3 hot air volume channels) 20 channels (15 temperature measurement channels + 5 hot air volume channels, special customized 40-80 channels + 5 hot air volume channels) |

| Equipment collection accuracy | ±0.5℃ |

| Device sampling frequency | 0.1-10S |

| Temperature data range | 0℃ - 750℃ |

| Temperature measurement resolution | 0.1℃ |

| Internal operating temperature range of the device | 0-85℃ |

| Does the battery support charging? | Support charging |

| Data transmission method | USB Transfer |

| Data storage channel selection | 20 groups of channel selection |

| Real-time display of internal temperature of the device | Display screen display/software display |

| Displays the thermocouple type | K-Type |

| Safety certification mark | CE |

Related materials

RCMK Reflow Oven Performance Test Kit

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you