What problems can we solve

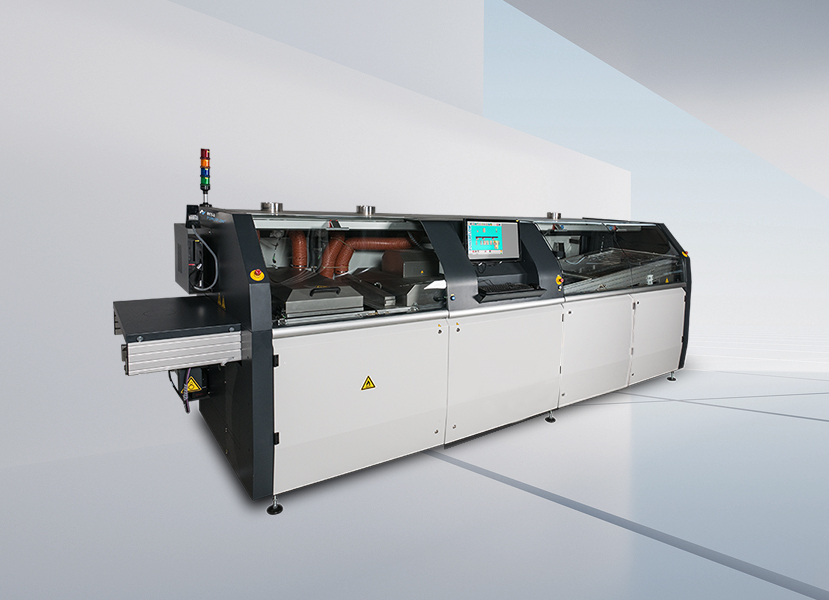

Wave soldering performance testing scenario

Scenario: Wave soldering quality depends on tin temperature, contact time, chain speed, and track performance.

Pain Point: It’s hard to measure tin temperature and contact time accurately, and track performance is tough to check.

Solution: Use the WTT test kit to measure tin temperature and contact time, and test track performance to check equipment.

Product Solutions

Real-time monitoring of reflow temperature and multiple parameters

Scenario: Wave soldering needs real-time monitoring of temperature, motor speed, and vibration.

Pain Point: Old methods can’t monitor all these at once, so problems are missed and production stops.

Solution: Use WAPS for 24/7 monitoring and to track temperature and DIP contact time for each PCB.

Product Solutions

Wave soldering temperature measurement scenario

Scenario: Wave soldering needs precise control and measurement of solder paste temperature and each temperature zone.

Pain Point: Regular temperature equipment isn’t accurate enough for these complex needs.

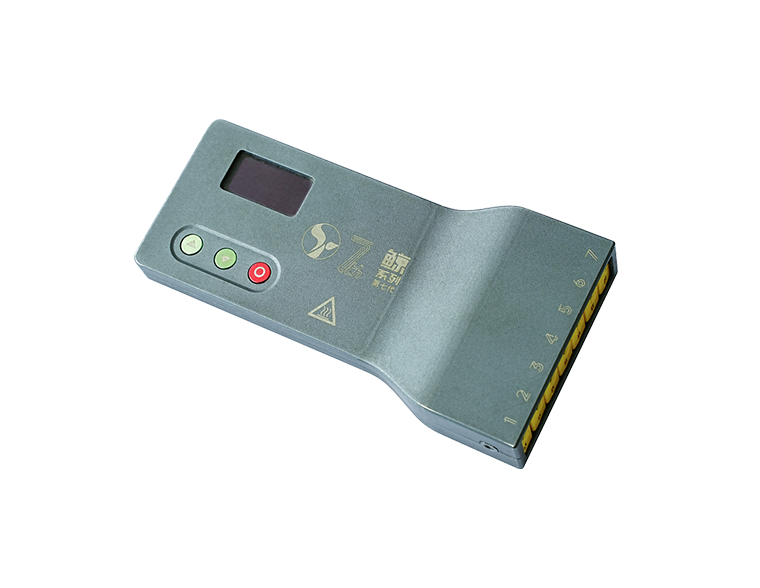

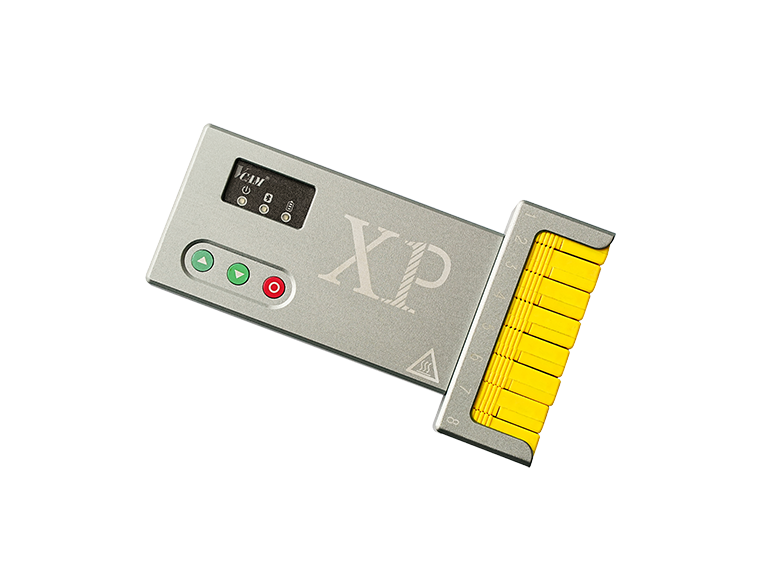

Solution: Offer customizable oven profiler with 6-32 channels to meet wave soldering requirements.

Product Solutions

Our solution is being applied in these industries