-

Product Value

-

Core functions

-

Applicable scenarios

-

Product parameters

-

Related materials

-

Recommended products

Product Value

Reduce production losses

Discover track deformation and vibration abnormalities in advance to avoid line stoppage or waste caused by board jams or board drops

Ensure equipment performance

Provide benchmark data support when new equipment is introduced or debugged to ensure production stability

Optimize maintenance efficiency

Quantify maintenance effects through data, adjust maintenance strategies in a targeted manner, and reduce operation and maintenance costs

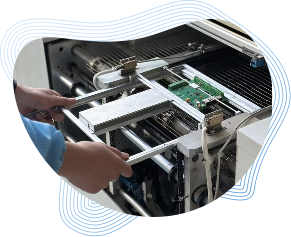

Contactless safety detection

The measuring rod does not touch the track to avoid scratches or secondary damage, and is suitable for high-precision equipment requirements

Core functions

Deformation test

Record track deformation and identify subtle changes

Chain speed test

Monitor chain speed stability and prevent patch deviation

Vibration testing

Capture vibrations and analyze production impact

Slope test

Quantify the slope to ensure smooth transmission

Parallelism test

Detect horizontal deviation and prevent the risk of board jam

Temperature test

Monitor ambient temperature and analyze thermal effects

By Pass Monitoring

Real-time data collection without interfering with production

Applicable scenarios

Product parameters

| Temperature accuracy | +0.5℃ |

| Temperature resolution | 0.1℃ |

| Internal temperature range of the instrument | 0-85℃ |

| Instrument sampling frequency | 0.05-10S |

| Supply voltage | 5V1A |

| Operating temperature | -40°C to 85°C |

| Size | L184xW115xH30 mm |

| Sensor parameters | Resolution threshold (@1Hz) <1mg Non-linearity <0.1%FS and <0.02g Deviation calibration <2mg |

| Deformation measurement range | 16mm |

| Deformation measurement accuracy | ±0.2mm |

| Inclination measurement range | ±20° |

| Inclination measurement accuracy | ±0.2° |

| Vibration measurement range | ±2G |

| Vibration measurement accuracy | 5% |

Related materials

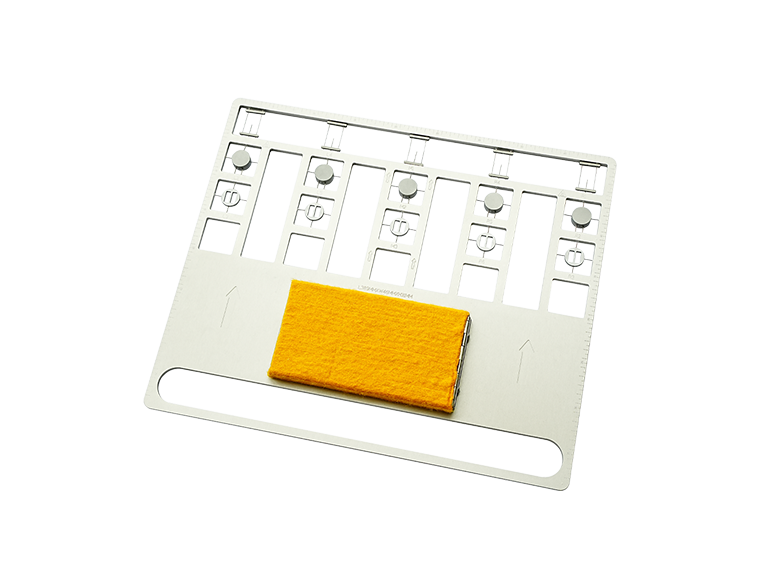

RPT Rail Performance Test Kit

Professional thermal engineering monitoring solutions make temperature control simple and efficient

Contact us to let our solutions help you