As a bellwether of the global electronics manufacturing industry, NEPCON Shanghai will be held from April 22 to 24! This exhibition focuses on the theme of "intelligent manufacturing, smart factory", bringing together more than 500 top companies from around the world to showcase the latest technologies in the entire electronics manufacturing industry chain.

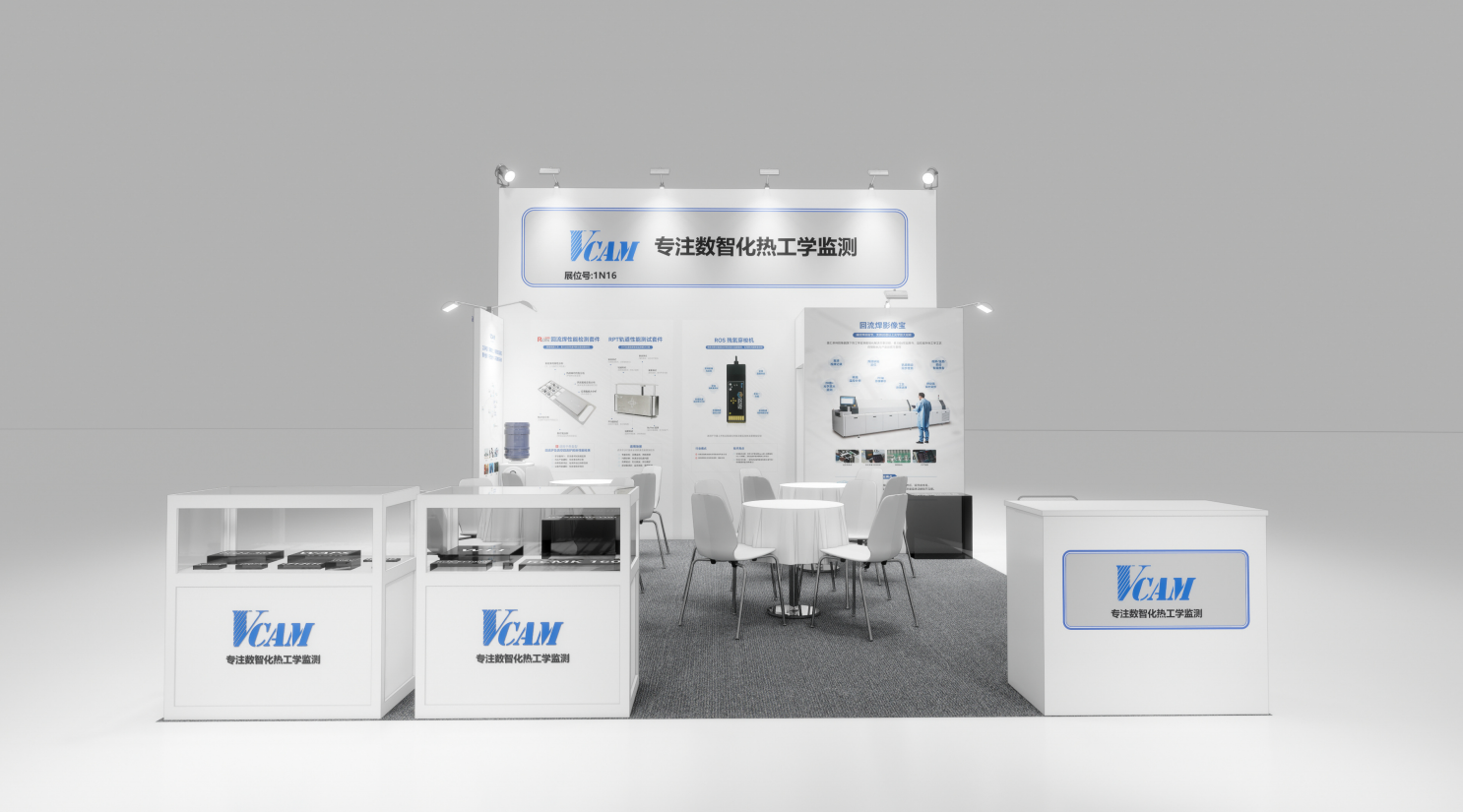

As a leading company in the field of thermal engineering monitoring in China, Vcam was invited to present its core solutions for the digitalization of thermal engineering processes, and explore with you the new future of digital management of thermal engineering!

Core pain points of the industry

The soldering process is the "invisible heart" of electronic manufacturing. The accuracy and stability of its temperature directly determine the reliability of manufactured products. Every soldering point is the "lifeline" for the long-term operation of the equipment.

1. Poor process stability and large yield fluctuations

- Nitrogen leaks are difficult to locate, the furnace environment fluctuates, and thermal balance is out of control (such as large temperature difference between fixed edge and movable edge), resulting in frequent defects such as tombstones, cold welding, and bottom parts falling off.

• Process parameters rely on manual experience adjustment and lack data support, resulting in a high risk of solder joint breakage.

2. Equipment efficiency and high operation and maintenance costs

- Equipment aging causes track deformation, chain speed fluctuations, and increased risk of unplanned downtime; traditional detection tools cannot capture hidden defects in real time, and maintenance efficiency is low.

• High energy consumption and lack of quantitative analysis tools, energy-saving optimization has no basis.

3. Insufficient multi-dimensional monitoring capabilities

- Traditional solutions only monitor a single parameter (such as temperature or residual oxygen), cannot globally evaluate the furnace status, have poor adaptability, and are difficult to accommodate complex scenario requirements.

Vcam's "Four Diagnostic Methods of Traditional Chinese Medicine" enables the digitalization of welding processes

Vcam uses the four-dimensional intelligent diagnosis of "looking, smelling, asking and feeling" - from visualization of the welding process in the reflow oven, real residual oxygen distribution test, and in-depth physical examination of the entire equipment, to create a full-link "health management" for the welding process, leaving no place for quality risks to hide, and both yield and efficiency leapfrogging.

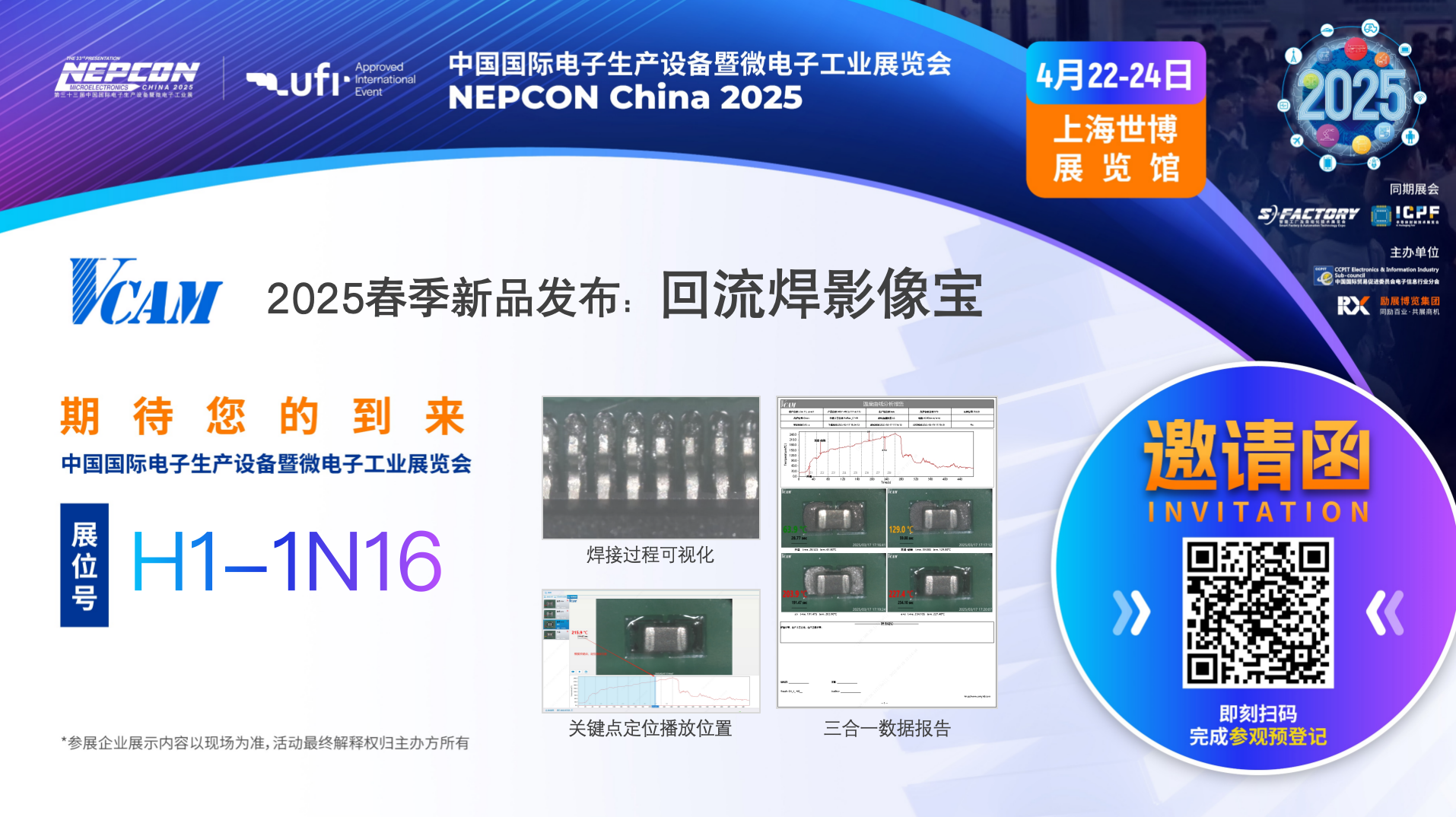

Pain point solution: Real-time recording of component welding dynamics, accurate capture of defects such as tombstone formation, cold welding, part dropout, displacement, and application verification of new processes and new solder paste materials, saying goodbye to the era of "no data" blind adjustment.

Value: Visualize the process, and make hidden defects invisible

?【Smelling】ROS residual oxygen shuttle

Pain point solution: Shuttle test the true distribution of residual oxygen in the entire nitrogen furnace (from entering the furnace to leaving the furnace), quickly locate the leakage point, reduce nitrogen waste, and improve welding reliability.

Value: Digital presentation of residual oxygen content curve, visible reduction of yield fluctuation

?【Asking】PIS24-365 furnace temperature real-time monitoring intelligent system

Pain point solution: Real-time monitoring is performed 24 hours a day, 365 days a year to generate the furnace temperature curve of each board, as well as data monitoring such as chain speed, track vibration, oxygen content, motor speed, etc. in each area.

Value: Fill the blind spots that cannot be monitored in the cavity of the reflow soldering equipment, and generate a unique and traceable digital identity for each PCB.

?【Feeling】RCMK reflow performance test kit

Pain point solution: In-depth "physical examination" of reflow soldering equipment performance, quantitative evaluation of thermal performance, prediction of aging trends, and reduction of unplanned downtime risks.

Value: Full-cycle management of equipment health, qualified equipment before commissioning, data comparison before and after maintenance, saving operation and maintenance costs.

Sincerely invite you to visit

VCAM has been deeply involved in the field of intelligent manufacturing for more than 20 years. With the digitalization of thermal engineering processes as the core, it provides global customers with one-stop digitalization solutions for welding processes, including furnace temperature testing, real-time equipment monitoring, equipment performance evaluation, and welding process visualization.

Time: April 22-24 9:00-17:00

Location: Shanghai World Expo Exhibition & Convention Center (No. 1099, Guozhan Road, Pudong New Area)