As a key link in electronic manufacturing, reflow soldering technology plays a decisive role in product quality and production efficiency. If you have a reflow soldering machine that has been used for many years, do you know how to understand its "health" status? For humans, "health" or "sub-health" will affect work efficiency, and the same is true for equipment.

Scenario Analysis

In the increasingly sophisticated manufacturing industry, there are various types of reflow equipment, whether it is ordinary reflow, nitrogen reflow or vacuum reflow, the stability and optimization of its performance are crucial. However, equipment troubleshooting, equipment performance testing, maintenance effect evaluation and new equipment performance comparison often face the problem of lack of data.

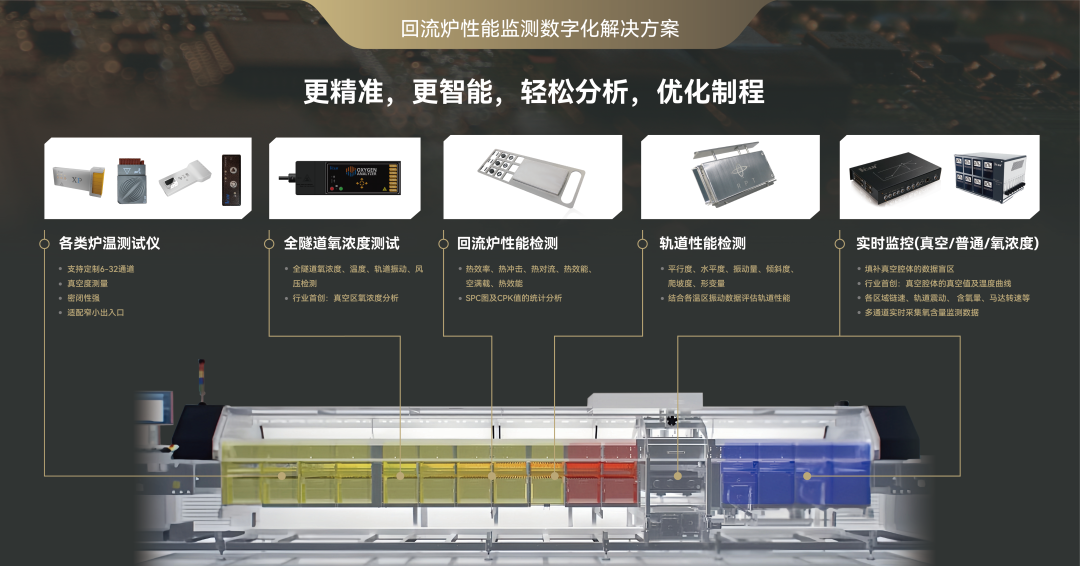

In this regard, the RCMK reflow soldering inspection kit provides a perfect solution.

It can accurately locate equipment failures, such as parts falling off in the reflow or fan speed not meeting the standard, and find the root cause of the problem through data analysis. At the same time, it can record and compare the stability of the equipment before and after maintenance, and evaluate the maintenance effect by reducing temperature fluctuations and improving the equipment capability index. For new equipment, RCMK can comprehensively evaluate its performance and compare it with old equipment to clarify the advantages and performance differences, providing a basis for optimizing processes and allocating tasks.

In short, the RCMK reflow soldering inspection kit, with its comprehensive functions, provides you with strong support and accurate data in equipment troubleshooting, equipment performance testing, equipment maintenance, and new equipment evaluation, helping to improve production efficiency and product quality, and safeguarding the development of your enterprise.

Scene Reproduction

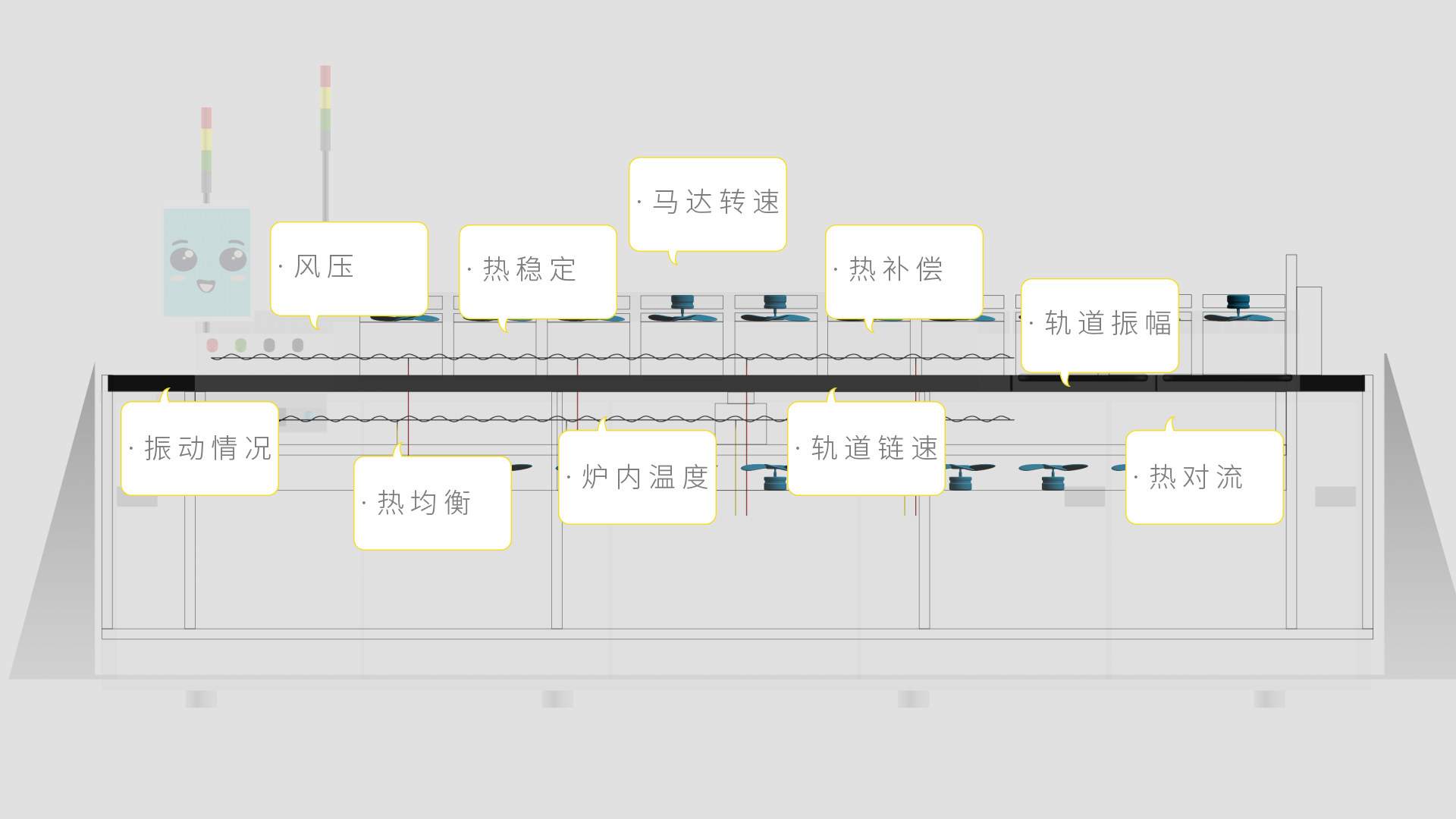

You see, here is a reflow machine that has been in the factory for several years...

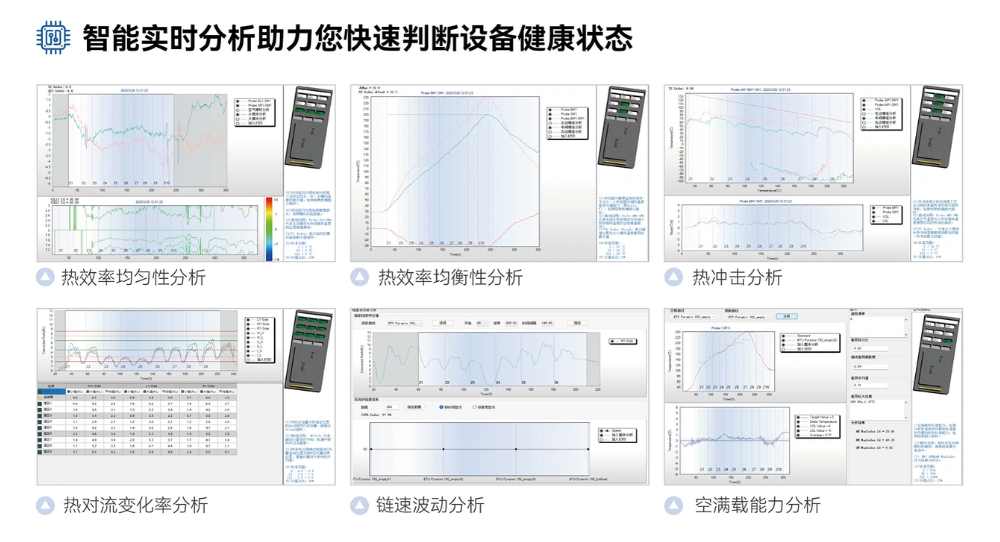

After multiple tests, Rcmk can generate stability analysis of equipment chain speed, thermal efficiency, empty and full load performance, and environmental thermal compensation capability, and can generate SPC charts and statistical analysis of CPK values.

If you also want to do a comprehensive "thermal engineering physical examination" for your reflow soldering equipment, please come to the "VCAM Thermal Engineering Monitoring Center" to find our "Dr. R"!

Industry White Paper

This year, VCAM combined the industry's practical testing experience and the challenges and problems faced by more than 200 companies in the reflow soldering process, as well as their expectations and suggestions for solutions, and launched the "2024 Reflow Oven Market Research and Oven Temperature Monitoring Series White Paper" in order to achieve technological innovation and improvement.

More personalized solutions...

Let us work together to create a better future, help the industry upgrade, and create excellent quality!

We look forward to your joining us to write a brilliant chapter in the field of welding!