In the wave of intelligent manufacturing, the stability and accuracy of each process are crucial. Today, we will share a customer case about the successful solution of the reflow soldering equipment problem and see how the RPT track performance tester has become a powerful assistant for customers.

Client background and problem

An Indian customer with more than 20 production lines focuses on the production of servers and 3C digital products (such as fruit phones, etc.), so its customers have strict requirements for product quality control.

Problem analysis and customer needs

VCAM process experts conducted an in-depth analysis of these issues. Reflow equipment is a key link in the production line, and the stability of its components is directly related to the quality of the product.

For equipment that has been used for more than 8 years, some components may be aged or have degraded performance. Therefore, customers are eager to use data to accurately locate and analyze problems such as board jamming and part dropout in reflow soldering equipment, find the root cause of the problem, and seek effective solutions.

VCAM Suggestions and Solutions

In order to meet the needs of customers, VCAM proposed to give priority to data detection of track performance.

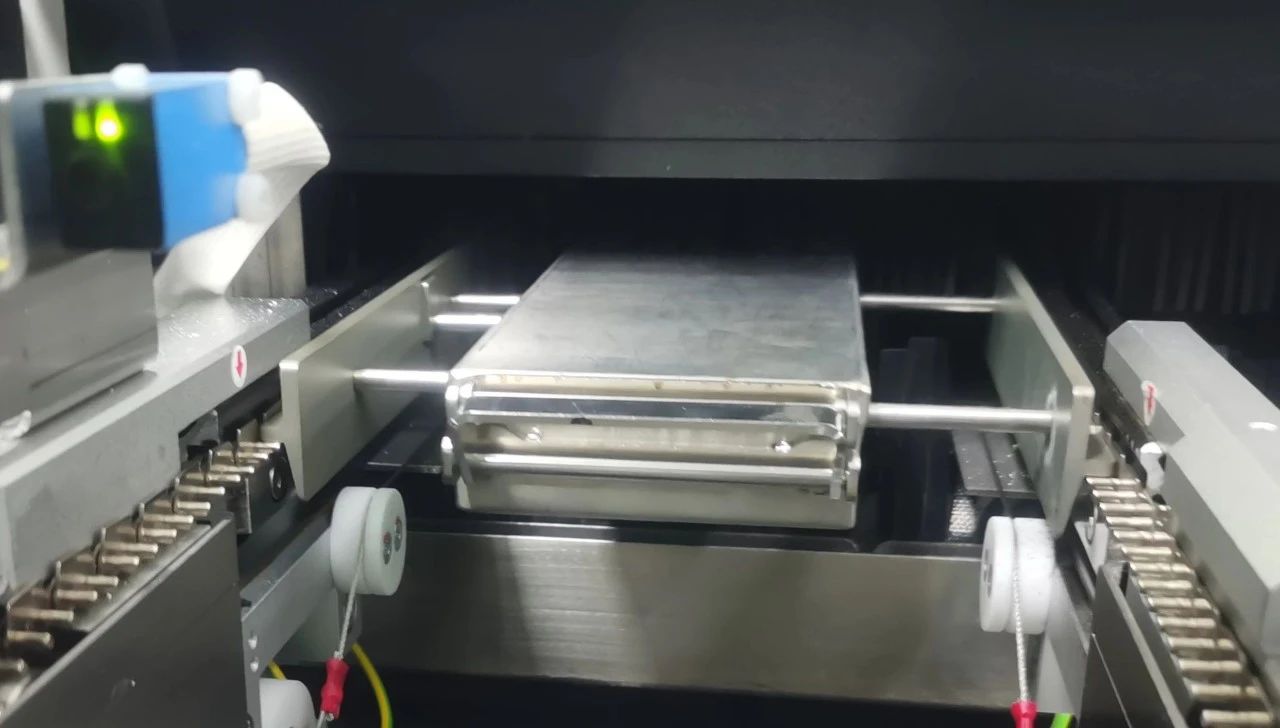

Therefore, we chose the RPT track performance test kit, which can conduct comprehensive tests on track deformation, track chain speed, track vibration, track climbing grade and track parallelism.

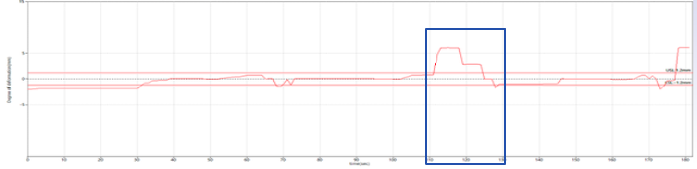

01 Demo test

During the first demo test, the RPT performance test equipment encountered a board jam problem in the third temperature zone of the reflow.

But it was this test that allowed us to collect valuable data: the track deformation reached its peak value during the period of 110s-130s, with the maximum deformation being 6.05mm and the minimum being -1.96mm;

Track parallelism reaches its peak during 120s-130s:

- The maximum angle deviation in the X direction is 1.09°

• The maximum angle deviation in the Y direction is 2.59°

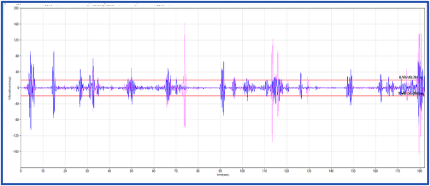

The track vibration also showed obvious abnormalities:

- Maximum vibration range in the X direction (left and right vibration): 163.13 mg

• Maximum vibration range in the Y direction (forward vibration): 92.26 mg

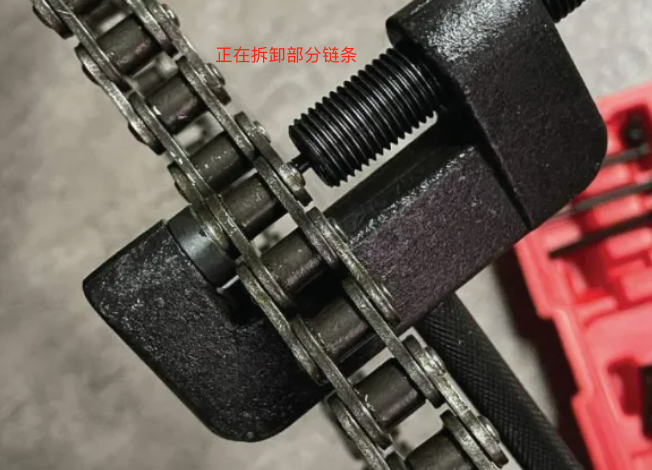

02 Maintenance of rows

Based on the test results, we conducted in-depth communication with customers and reflow soldering manufacturers and developed targeted maintenance plans.

The customer performed a series of maintenance on the reflow equipment track, such as shortening the track chain and cleaning the track with dry ice.

03 Post-maintenance inspection

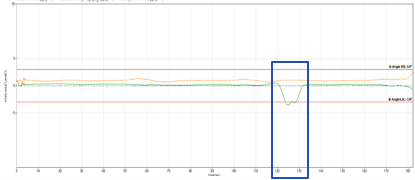

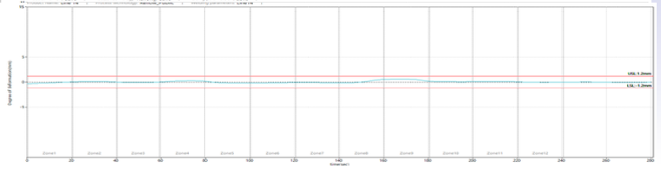

After the maintenance was completed, we once again tested the performance of the reflow equipment, and the results were encouraging:

• Track deformation:

The maximum deformation is 0.59mm, and the deformation is reduced by 5.46mm.

The minimum deformation is -0.30mm, and the deformation is reduced by 2.26mm.

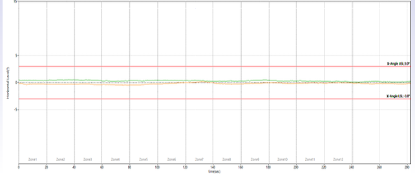

Track parallelism:

The maximum angle deviation in the X direction is 0.18°, and the deviation angle is reduced by 0.91°

The maximum angle deviation in the Y direction is 0.54°, and the deviation angle is reduced by 2.05°

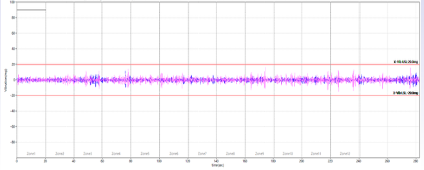

- Track Vibration Analysis:

The maximum vibration range in the X direction is: 11.76 mg, and the vibration range is reduced by 151.37 mg

The maximum vibration range in the Y direction is: 16.36 mg, and the vibration range is reduced by 75.9 mg

This successful case once again proves the outstanding performance of the RPT track performance tester in accurately locating track anomalies and monitoring track performance.

VCAM Rail Performance Testing Solution

Providing customers with comprehensive information such as vibration data of each temperature zone and track performance monitoring, helping customers to achieve stability and optimization of production lines.

On the road of intelligent manufacturing in the future, VCAM will continue to work with more digital equipment to provide more customers with professional and precise solutions, and jointly promote the transformation, upgrading and high-quality development of the manufacturing industry.